Steel cord conveyor belts (ST800/ST1000/ST1250/ST1400/ST1600/ST1800/ST2000/ST2250 etc.) are widely used in high strength, long distance and heavy load transportation of materials, and they are also used in high strength and short distance transportation of materials on special occasions.

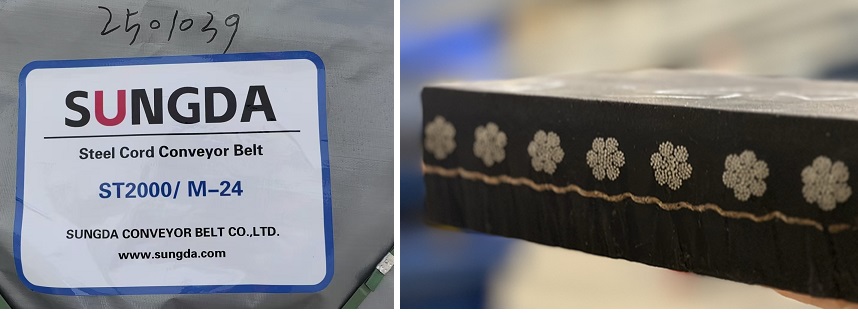

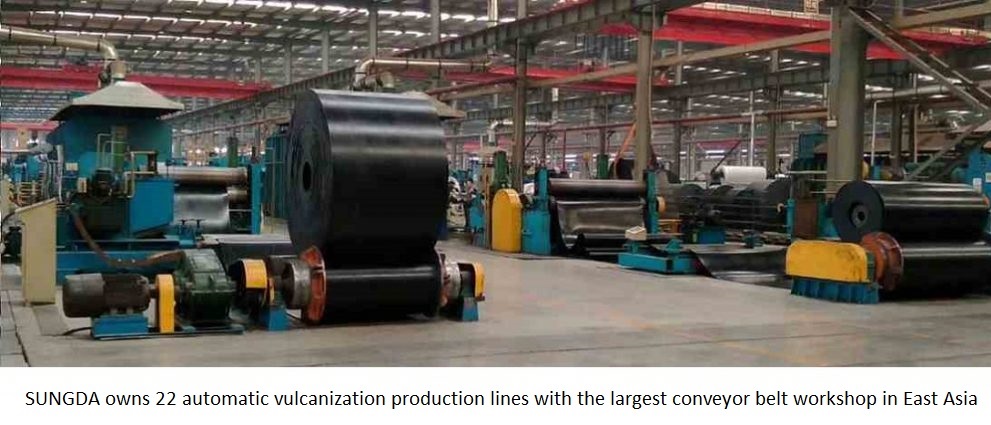

SUNGDA Conveyor Belt, part of the same group as JIENASI, is one of the largest steel cord conveyor belt manufacturers in China, boasting 22 state-of-the-art production lines. It utilizes "HIXIH" steel cords, the same brand used by Continental steel cord conveyor belts, combined with high-tensile, wear-resistant premium vulcanized rubber. This ensures exceptional performance in long-distance transportation, high-capacity conveying, and extreme operating conditions.

Characteristics

1. High tensile strength: The belts are suitable for large span, long distance transportation of materials.

2. Small elongation in use: The belts need only a very short take-up stroke distance.

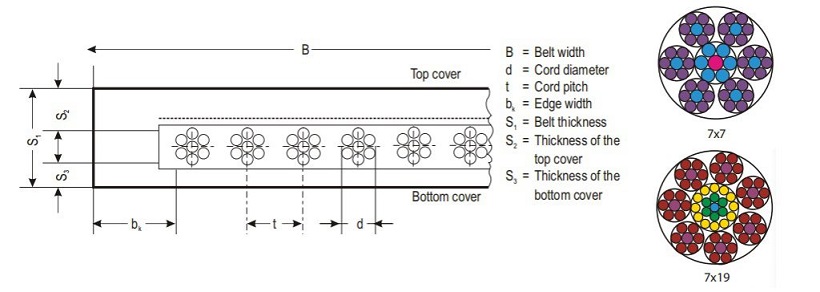

3. Small diameter of drive pulley: The belt body has a layer of longitudinally arranged steel cords as its skeleton, and thus is resistant to flex fatigue. Therefore, a drive pulley of smaller diameter can be used to make the equipment smaller.

4. High adhesion between rubber and steel cord: The steel cords are coated with zinc on their surface, and also the rubber used has the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in life.

5. Even tension of steel cords: Because of advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well balanced in running and difficult to run awry.

6. Good trough ability: As the belt body has no transverse skeleton, it is easy to from a deep trough, so the belts can load more materials and prevent the materials from escaping.

7. Inspection of the belt with X-rays: Users can use X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.

Steel Cord Conveyor Belt’s Cover Grade:

Rubber Cover Type

Characterization

Tensile

Strength

in Mpa(min)

Elongation

at break

%(min)

Abrasion

in mm³

(max)

Hardness

in SHA

Basic

Material

DIN – X

Extreme abrasion resistance,superior resistance to cutting & tearing

25

450

120

60±5

NR/SBR

DIN – Y

Excellent Impact and abrasion resistance

20

400

150

60±5

NR/SBR

DIN – W

Good abrasion resistance,superior resistance to cutting & tearing

18

400

90

60±5

NR/SBR

DIN – Z

Normal abrasion resistance and cutting & tearing resistance

15

350

250

60±5

NR/SBR

DIN – K

Flame Retardant (M HSA)

15

350

200

60±5

CR

G

Oil Resistant

15

400

200

60±5

NBR

C

Chemical Resistant

15

400

250

60±5

CR/IIR

E

Anti-Static

15

400

200

60±5

NR/SBR

HR

Heat Resistant+100℃~+175℃

15

400

200

60±5

SBR/EPDM

RMA – I

High abrasion resistance,superior

resistance to cutting &tearing

17

450

200

60±5

NR/SBR

RMA – II

Resistant to cuts and gouges,

flexible at lower temperatures

14

400

250

60±5

NR/SBR

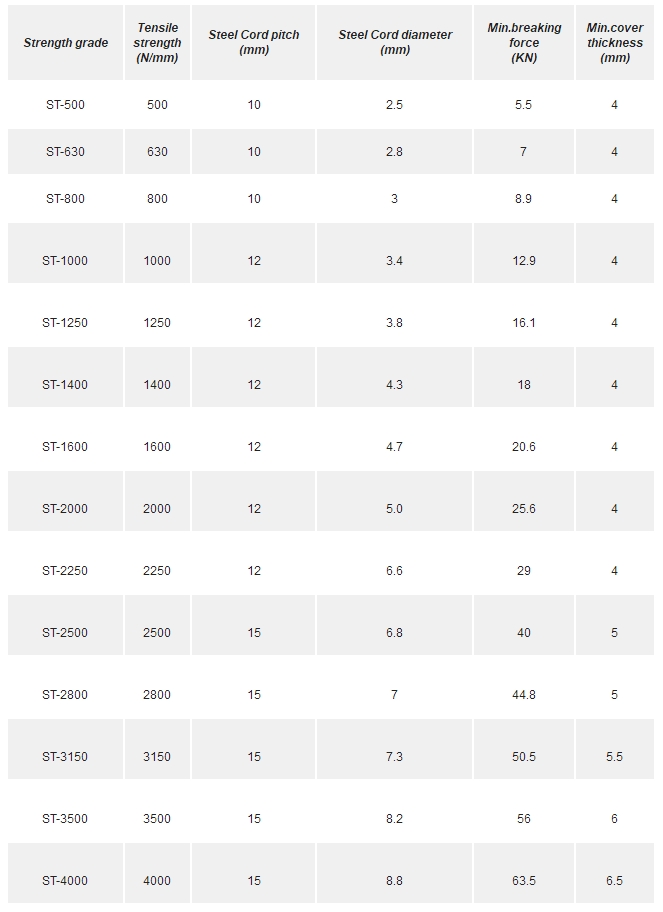

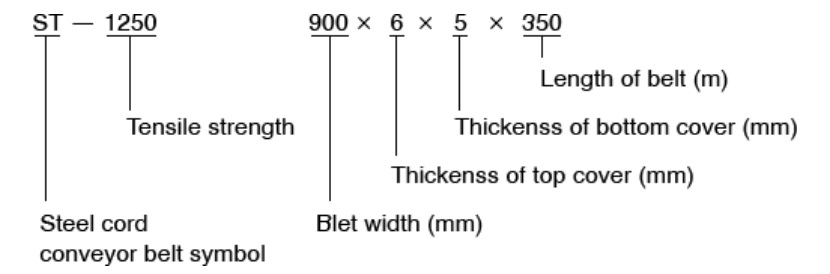

Steel cord conveyor belt’s key to symbol:

Compared with EP conveyor belts, steel cord conveyor belts are more complicated in the manufacturing process, which is mainly due to the following three reasons:

Since the manufacturing process of the steel cord conveyor belt is more complicated, the manufacturer is required to have very strong technical strength and a more advanced vulcanization production line, and have strict quality control processes before, during and after production, only advanced equipment and professional With a professional technical team, the manufacturer can ensure the production of high-quality wire rope conveyor belts to meet the needs of customers

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China