Trough conveyor roller idler / Carrying idler

The conveyor idler, also known as a conveyor roller, is a critical support and transmission component in conveyor systems widely used for bulk material handling in mining, cement, and coal industries. Its development has progressed from high-friction 18th-century wooden rollers to durable cast iron and steel, and finally to modern synthetics like HDPE and UHMWPE, which offer superior corrosion resistance and noise reduction.

Structurally, Thomas Robins’ 1892 patent for the three-roll troughed idler marked a milestone, shifting designs from simple flat beds to "V" or "U" shaped configurations that maximize load capacity. Simultaneously, open bearings evolved into sophisticated multi-labyrinth seals designed for harsh environments. Functionally, idlers have expanded beyond basic friction reduction to specialized roles such as belt tracking (self-aligning), impact absorption, and energy efficiency. Today, the integration of sensors has transformed them into "smart idlers" capable of real-time temperature and vibration monitoring for predictive maintenance.

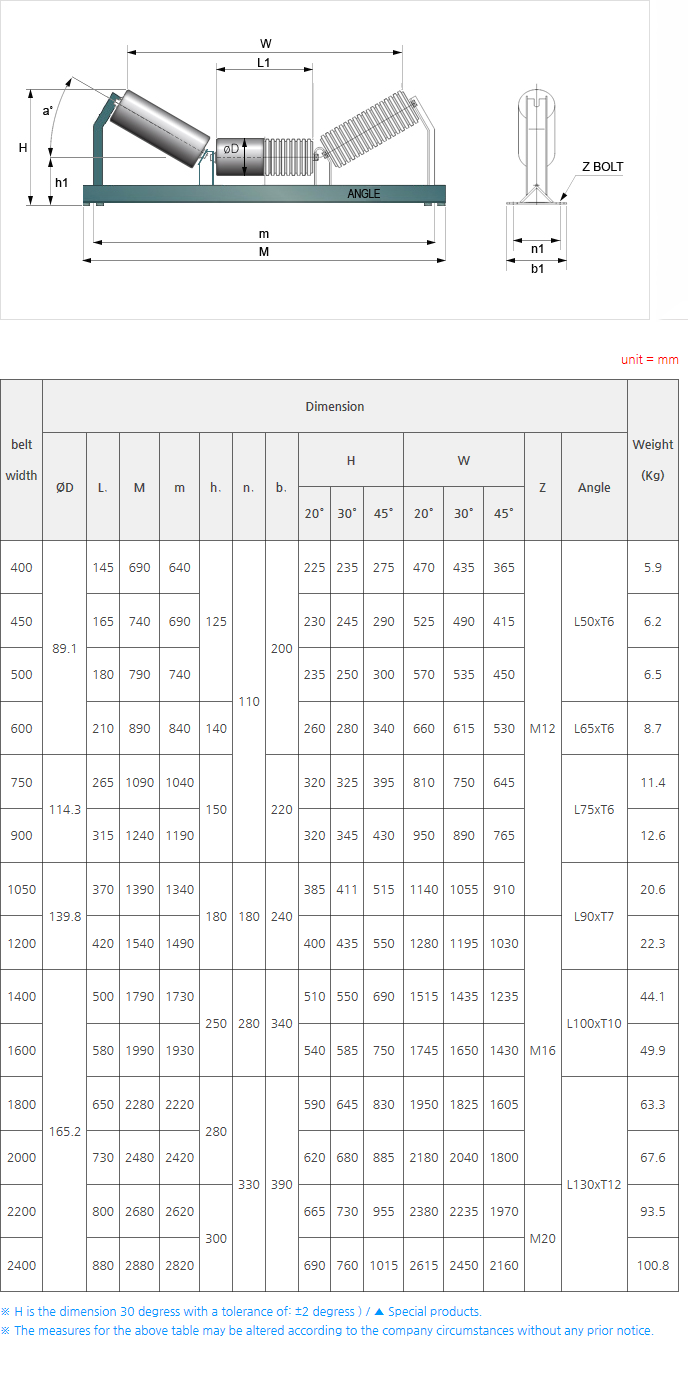

In practical applications, the troughing angle of the rollers varies according to different needs, with common angles being 20 degrees, 35 degrees, and 45 degrees. Larger angles create deeper troughs, making them suitable for transporting loose, easily rolling materials. Trouging rollers are widely used in industries such as mining, construction, agriculture, ports, and manufacturing for the transportation of materials like ores, coal, gravel, concrete, grains, and fertilizers. In these contexts, they play an essential role in stabilizing the conveying process, ensuring that materials do not slip off during transport. Proper selection and configuration of trouging rollers are crucial for maintaining the efficiency and stability of the conveyor system.

Detailed conveyor idler feature:

Conveyor idlers: Available in diameters ranging from 50 mm to 219 mm (2 1/2" to 8 5/8"), with lengths from 190 mm to 3400 mm, to suit a wide range of conveyor systems.

Idler Tube: Made from Q235 (equivalent to SS400/JIS G3101/EN10025/ASTM A36 ) steel for durability and strength.

Idler Shaft: Constructed from 45# (equivalent to DIN:C45/EN:C45/JIS:S45C/ASTM A1045 )steel for reliable performance.

Bearing: Equipped with single and double row deep groove ball bearings, with 2RZ and 2Z options available, and C3 clearance for enhanced efficiency and reduced friction.

Seals system: Features a grease retaining inner seal with multi-stage labyrinth design, along with a retention cap, to prevent dust and debris from entering the bearing.

Lubrication: Uses lithium soap type grease with rust inhibitors, to ensure smooth and reliable operation.

Welding technology: Utilizes mixed gas shielded arc welding for strong and consistent welds.

Painting technology: Offers a variety of painting options, including ordinary painting, hot galvanized painting, electric static spraying painting, and baked painting, to suit the specific needs of each application.

Overall, our conveyor idlers are designed and built to meet the rigorous demands of heavy-duty material handling systems, ensuring smooth and efficient operation and long-lasting performance.

Common Conveyor Idler Bracket Specification:

100% Moisture-proof packing that can completely keep roller and bracket from erosion of sea humidity for 90days.

Fast shipping that can reach every corner of the earth in 45days from order!

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China