The service life of conveyor idlers can be affected by several factors such as poor coaxiality of the conveyor idler shaft, internal structure, and processing technology. To address these issues, various improvements have been made to the conveyor idler seal, shaft coaxiality, bearing seat coaxiality, and processing technology. One of the most notable improvements is the redesign of the sealing structure, which combines contact and non-contact sealing to effectively prevent external dust and moisture from entering the bearing. These improvements can significantly enhance the performance and durability of conveyor idlers.

(1) The mechanism and scheme of the improvement of conveyor idler seal

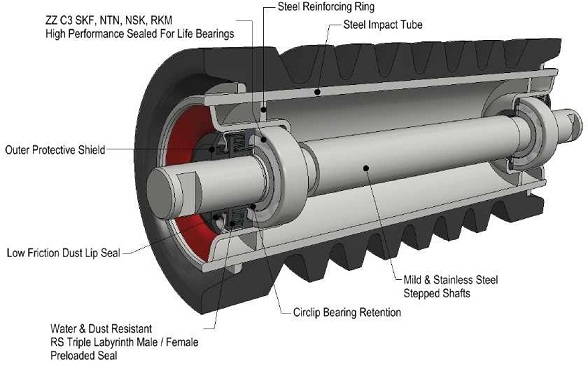

The function of the seal is to prevent external dust and moisture from entering the bearing. According to whether the seal is in contact with the relative moving parts, it can be divided into contact seal and non-contact seal. Contact seal is a seal in which the seal is in contact with its relative moving parts and has no gap, and the seal is in direct contact with the mating part; non-contact seal is a seal in which the seal and its relative moving parts do not contact, and there is a proper gap. There is no wear between. In view of the shortcomings of the original conveyor idler seal, a new type of seal ring structure was redesigned, as shown in Figure 2.

New type of conveyor idler internal structure

This new type of sealing structure combines contact sealing and non-contact sealing. The contact seal is made of oil-resistant rubber, which has good comprehensive mechanical properties, high resilience and wear resistance. It uses the interference between the rubber seal and the conveyor idler shaft to be tightly combined, thereby effectively solving the problem of waterproofing of the conveyor idler, and also has the effect of preventing dust from entering. The non-contact seal is an axial labyrinth seal, which is divided into an inner seal and an outer seal. A small tortuous gap is formed between the inner and outer seals to achieve the seal. The axial labyrinth seal has good dust-proof effect and low resistance. The seal can be sleeved along the axis, which is very convenient for assembly and disassembly. Therefore, the organic combination of the two can make the conveyor idler better realize the functions of waterproof and dustproof. Since the seal of the contact type seal is in direct contact with the counterpart, the friction is greater during work, so in the initial stage of use, the conveyor idler resistance is higher than that of the conveyor idler with non-contact seal, but its sealing layer is more and the sealing effect is greater. Well, after using for a period of time, the conveyor idler will turn more and more flexible.

(2) Improve the coaxiality of the conveyor idler shaft

In view of the unstable accuracy of the cold drawn optical shaft and the defects that cannot be compensated by the different shafts during transportation, etc., the round steel material is processed into a stepped shaft instead of the cold drawn optical shaft, and the coaxiality at both ends of the shaft is ensured by processing methods. Grinding is carried out on the bearing at both ends of the shaft.

(3) Improve the coaxiality of the bearing seat

In order to ensure the coaxiality of the two bearing seats, both the circumference and end faces of the bearing seat and the barrel skin are processed, so as to effectively overcome the problem of non-circular bearing seats or unequal end faces at the matching part of the shell during stamping. Thus, the coaxiality of the two bearing seats is ensured by processing means.

(4) Improvement of processing technology

Modify the processing sequence of the axial retaining ring grooving, first assemble the seal, set aside the axial displacement according to the standard requirements, and then process the axial retaining ring grooving, thus avoiding the problem of excessive axial movement, and effectively Ensure that the axial movement value is not greater than 0.7mm.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China