Is Manual Rust Removal Really Enough for Idlers in Coastal & Humid Environments?

In the procurement and acceptance of idlers (rollers) and frames, people are often attracted by the shiny finish of the final product, yet they easily overlook the "hidden works" beneath the paint—Surface Treatment.

According to international engineering statistics on corrosion protection, over 70% of coating failures (such as blistering, peeling, and early rusting) are not caused by the quality of the paint itself, but are attributed to improper substrate preparation. For idlers and frames that endure long-term vibration, impact, and open-air exposure, Shot Blasting is not merely a manufacturing step; it is the physical foundation that determines the product's service life.

1. Core Principles: More Than Just "Rust Removal"

Many mistakenly believe that the purpose of shot blasting is simply to wipe rust off the steel surface. This is a major misunderstanding. From a micro-physical and chemical perspective, shot blasting fulfills two irreplaceable missions:

Thorough Removal of "Mill Scale"

During the hot rolling and cooling process, a hard, brittle, blue-black layer known as "Mill Scale" forms on the steel surface.

Although this scale looks dense, its electrode potential differs from the internal steel matrix. If one simply paints directly over the mill scale to save time, moisture will eventually penetrate the paint film in humid environments, creating "micro-battery corrosion" between the scale and the steel.

This electrochemical reaction causes the scale to flake off in chunks, taking the paint with it. This explains why many frames lose large patches of paint even when the paint film itself seems intact. Only the high-speed impact of shot blasting can thoroughly crush and strip this scale, restoring the steel to its "true color."

Creating an "Anchor Profile"

A smooth steel plate has low surface energy, making it difficult for paint to adhere—much like trying to stick tape onto dusty glass.

During shot blasting, countless steel shots impact the substrate at high speeds, creating a micron-level roughness known in engineering as an "Anchor Profile." This rough surface multiplies the effective surface area of the steel, allowing the paint to cure and embed itself into the steel texture like millions of tiny "claws," forming a powerful mechanical interlock.

Without shot blasting: Paint "floats" on the surface.

With shot blasting: Paint "grows" onto the steel.

2. Necessity Analysis Under Conveyor Operating Conditions

While manual rust removal might be barely acceptable for ordinary static structures, shot blasting is a "must-have" for idlers, pulleys, and frames.

Resistance to Vibration Peeling: Conveyors generate continuous high-frequency vibration during operation. If paint adhesion relies solely on weak intermolecular forces (Van der Waals forces), the coating will easily crack under vibration. Only the mechanical interlocking provided by Sa 2.5 (Near-White Metal) shot blasting can resist this fatigue-induced peeling.

Elimination of Welding Stress: Frames are typically welded from steel sections, resulting in significant thermal stress at the weld seams. The shot blasting process acts as an intensive "hammering" (shot peening) on the workpiece, effectively relieving welding stress, reducing future distortion, and improving the installation precision of the idler sets.

3. Modern High-Efficiency Processing Technologies

To meet the dual demands of high quality and high capacity, modern production has abandoned inefficient manual processing in favor of automated shot blasting lines. Processes are specialized based on component characteristics:

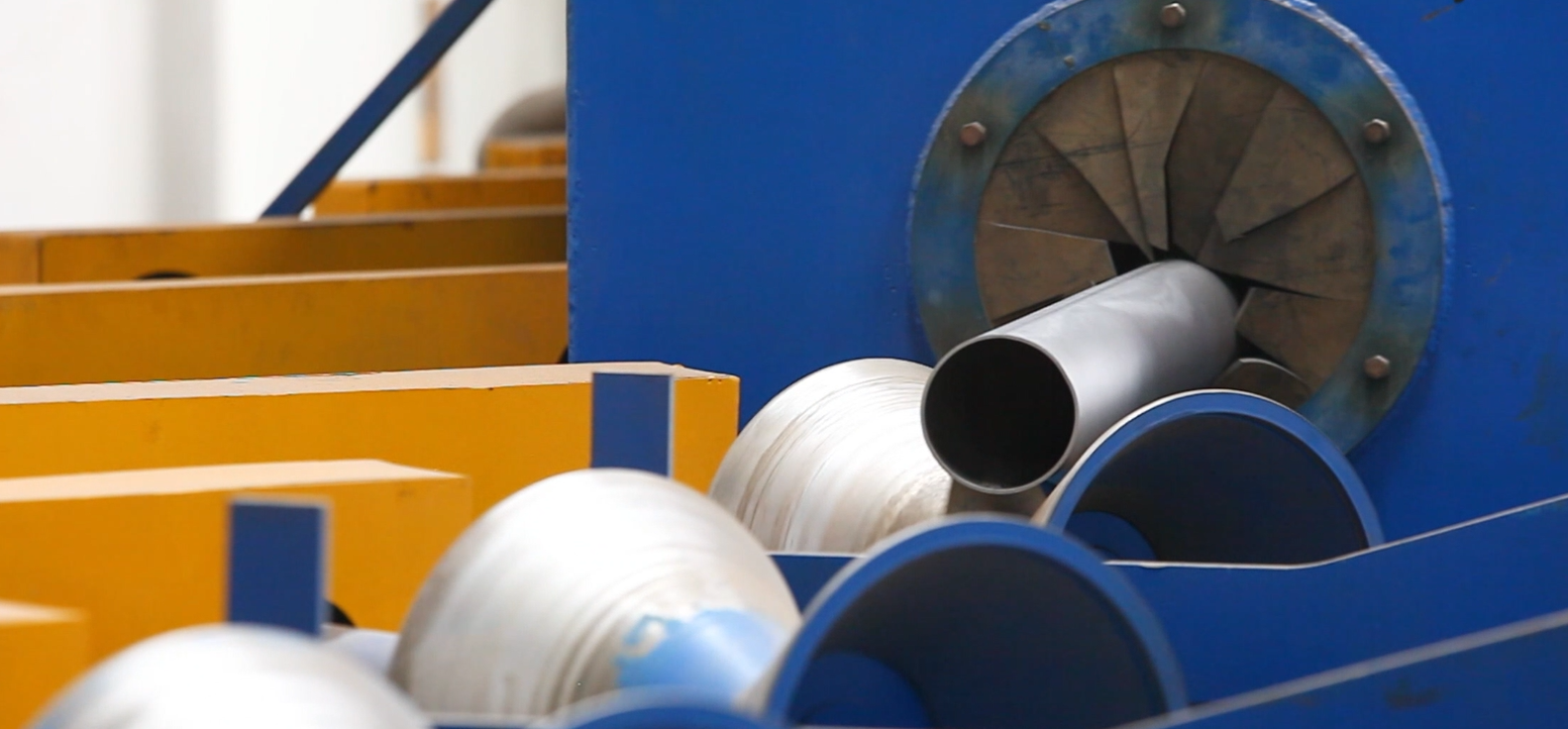

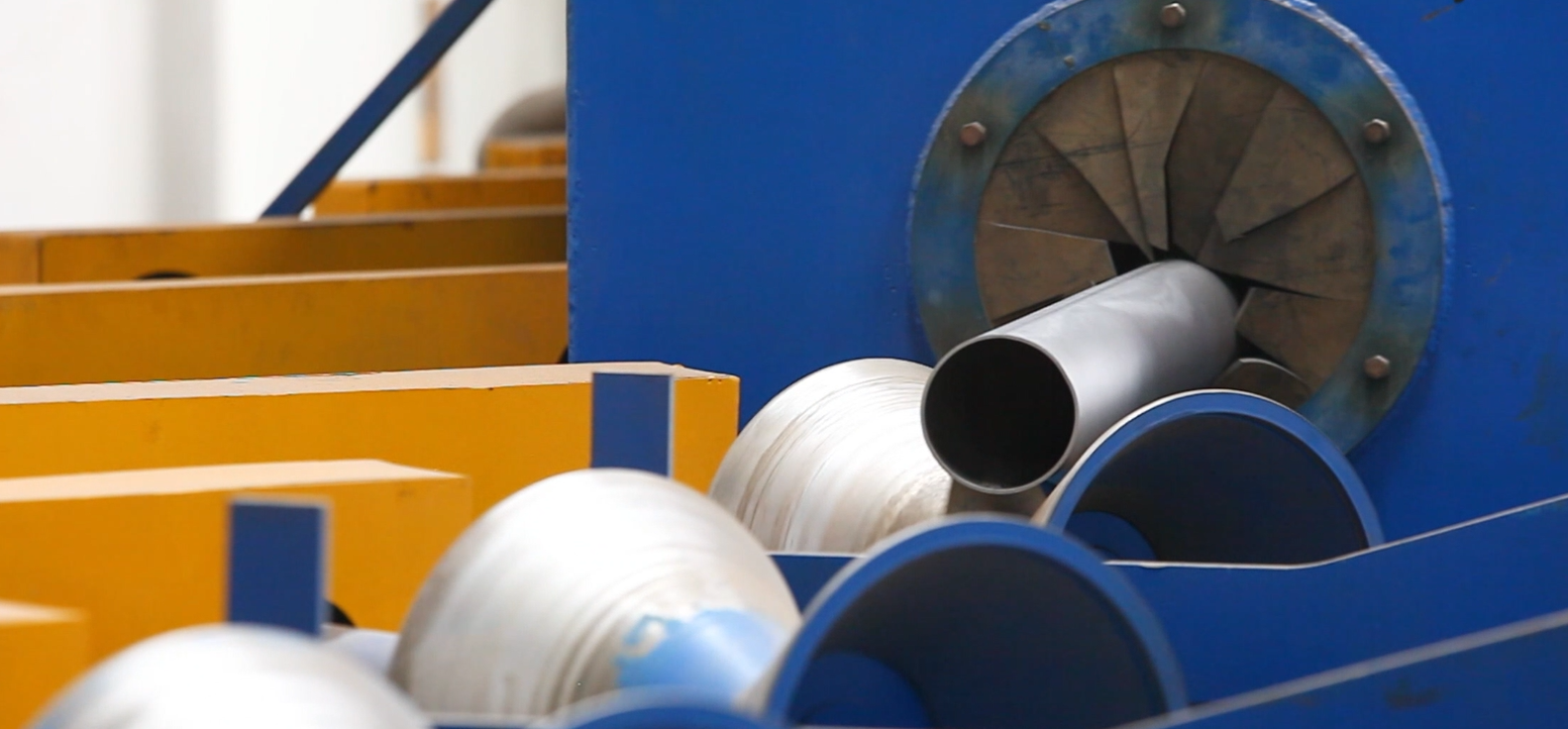

Specialized Process for Idler Tubes:

Utilizing Rotary Pass-Through Shot Blasting. The tubes rotate while moving forward, ensuring that the high-speed stream of shots covers the surface from multiple angles. This guarantees a uniform anchor profile around the entire circumference of the tube wall, laying a perfect foundation for subsequent spraying.

Specialized Process for Large Frames:

Utilizing Hanger-Type or Pass-Through Shot Blasting Chambers. Addressing the complex structure and dead corners of frames, these systems use centrifugal force to project shots at extremely high speeds onto the workpiece. Even internal corners and hole edges are cleaned down to the bare metal.

4. JIENASI's Practices: Putting Theory into Action

At JIENASI, we are equipped with complete automated shot blasting systems:

Our specialized idler tube shot blasting machine delivers extremely high operational efficiency, ensuring every tube meets coating standards before assembly. Furthermore, for large structural components, we have invested in dedicated large-scale frame shot blasting machines.

Actual Performance Data:

Our large-scale equipment possesses powerful cluster processing capabilities. A single cycle takes only about 10 minutes to complete deep-layer shot blasting for approximately 80 frames (depending on specifications) at once.

This efficient and standardized process configuration not only ensures that every product delivered by JIENASI possesses excellent corrosion resistance and adhesion but also guarantees our ability to respond rapidly to large-volume urgent orders.