In the manufacturing of steel conveyor idlers, the selection of tube material directly determines product strength, deformation resistance, wear performance and long-term reliability. For high-load, long-distance and harsh-environment conveyor systems, the steel tube must provide stable mechanical performance and consistent quality.

GB/T 700 Q235B, as the primary material for idler tubes, a structural carbon steel widely adopted across industries and proven to perform consistently under mining, quarrying, cement, ports, and bulk-material handling applications. Many international buyers reference their own national steel standards, which often leads to questions about equivalence. This article explains why Q235B meets the performance requirements of steel idler tubes and clarifies its equivalence to major global standards including the United States, Europe, Japan, Southeast Asia, India, and Australia.

Chemical Composition & Performance Characteristics of Q235B

Q235B is a high-ductility, low-carbon structural steel with a balanced composition that ensures weldability, cold-formability and impact resistance. Its typical chemical range is: Carbon ≤ 0.20%, Silicon ≤ 0.35%, Manganese 0.30–0.70%, Sulfur ≤ 0.045%, Phosphorus ≤ 0.045%. The core alloying element Manganese (Mn) contributes to strength and hardness, while controlled levels of Carbon (C) ensure the tube remains weldable and resistant to brittle failure. Low impurity elements S and P keep the steel stable during welding and rotary operation, reducing crack risk. These characteristics make Q235B highly suitable for conveyor idlers subjected to continuous rotational load and long-term environmental exposure.

Why Q235B Is Ideal for Idler Tube Applications

For conveyor idlers, the tube must withstand impacts, cyclic loading, bearing-housing press fits, and external abrasion. Q235B exhibits a yield strength of approximately 235 MPa and tensile strength of 370–500 MPa, sufficient for standard and heavy-duty rollers. Its ductility minimizes deformation during bearing housing assembly, ensuring accurate alignment and smooth rotation. The steel also performs well in machining, welding, and anti-corrosion treatments such as galvanizing or powder coating. For environments requiring higher hardness or thicker walls, Q235B can be upgraded to higher grades (such as Q345) while maintaining compatibility with standard manufacturing processes.

Performance-Critical Elements and Their Influence

Several elemental components directly influence the long-term performance of idler tubes:These elements collectively ensure that Q235B idler tubes maintain roundness, structural integrity, and resistance to mechanical stress in daily operation.

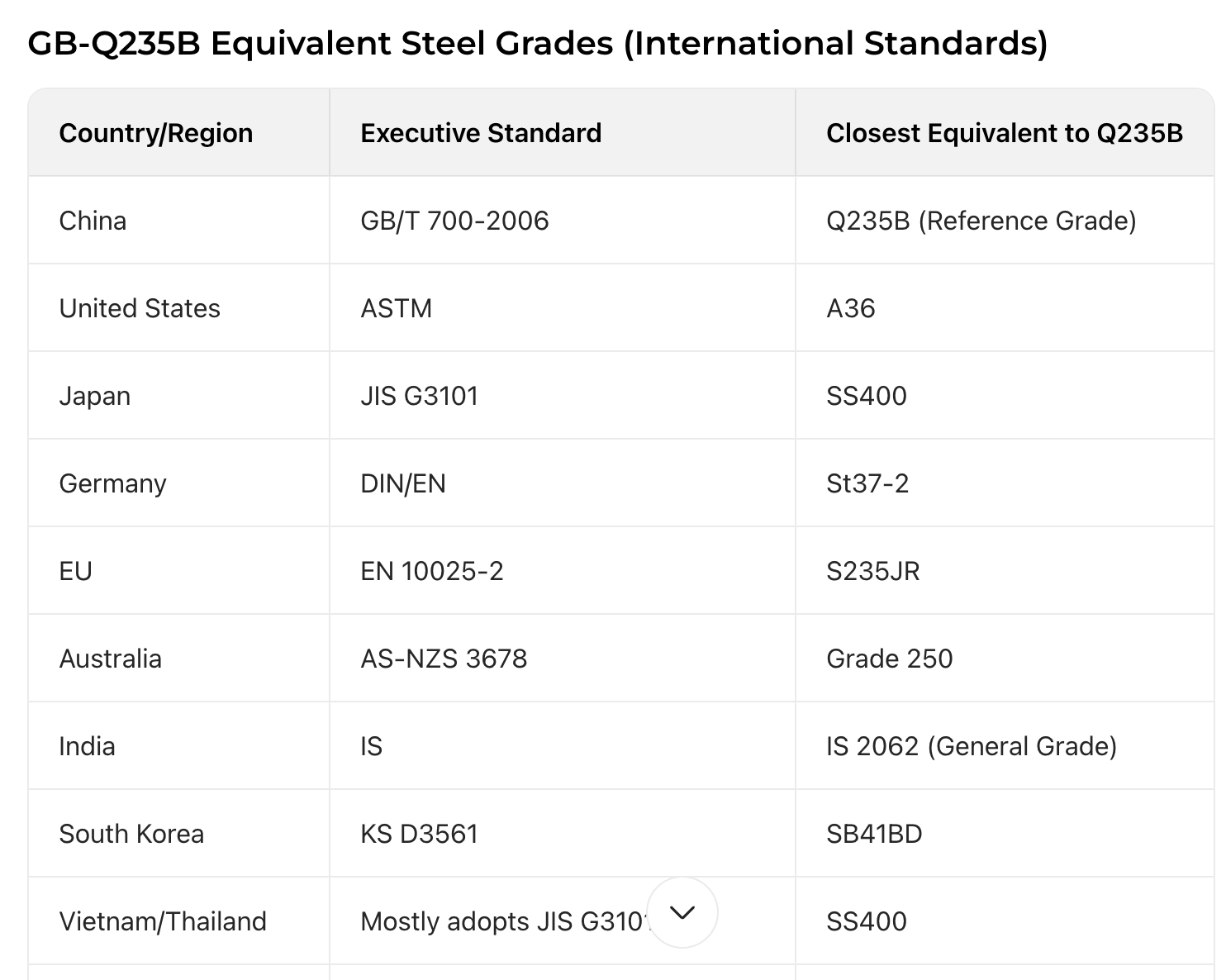

International Equivalent Grades to Q235B

Although steel naming conventions differ globally, many countries use materials with nearly identical chemical and mechanical profiles. Below is a summary of internationally recognized equivalents commonly seen in idler tube procurement projects.

Why Q235B Aligns Seamlessly with Global Client Requirements

Despite differences in naming conventions, these international grades share the same performance attributes essential for conveyor idler tubes: structural strength, weldability, cold-working adaptability, and predictable behavior under rotational fatigue. Q235B’s chemical range and mechanical properties position it as a universal structural steel category accepted across global industrial applications. When applied in idler tube manufacturing, Q235B delivers the required durability, concentricity stability, and resistance to mechanical deformation. This ensures compatibility with global conveyor designs used in mining, aggregates, cement, steel mills, and port logistics.

Q235B is a proven, globally equivalent structural steel that fully satisfies the mechanical, chemical, and performance demands of steel conveyor idler tubes. Its alignment with multiple international standards—including ASTM A36, EN S235JR, JIS SS400, IS 2062 E250, AS 3678 Grade 250 and Southeast Asian equivalents—ensures confidence in cross-border procurement and technical communication. By selecting Q235B and enforcing strict quality control, JIENASI delivers stable, reliable, and internationally compatible idler components for a wide range of industrial applications.Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China