As the main component of the belt conveyor, the conveyor idler is distributed under the belt conveyor belt, mainly used to support the belt and bear the load, shock absorption, avoiding belt misalignment, cleaning the belt is also its main function, therefore, its quality and correct selection, plays an important role in the service life, safe and stable operation and energy consumption of the whole belt conveyor, the guide recommended idler is suitable for ordinary belt conveyor with bandwidth of 500~2400 and high strength belt conveyor with high speed, high capacity and long distance, it is widely used in metallurgy, coal, hydropower, building materials, chemical industry, seaport, wharf and other fields, and can transport all kinds of bulk, granular, bulk materials and articles with a accumulation capacity of 0.5~2.5t/m³

|

No. |

project name |

performance index |

|

1. |

Working life |

Normal use, the life is not less than 50000 hours, and the damage rate during the effective use period is not exceed 5% |

|

2. |

Rotational resistance coefficient of the idler |

Factory laboratory test: 0.010; Under the engineering service conditions: 0.020. |

|

3. |

Radial run-out |

0.5mm (idler length <550mm) 0.6mm (idler length 550-950mm) 1.0mm (idler length> 950-1600mm) 1.2mm (idler length> 1600mm) |

|

4. |

Axial displacement of the idler |

0.5mm |

|

5. |

idler dust and water volume |

After the idler runs continuously in the container with dust for 200 hours, the dust does not enter the sealed grease chamber. After continuous operation for 72 hours under water condition, the water intake is 10g. |

|

6. |

idler axial bearing capacity |

10 KN (idler diameter 108mm) |

|

15 KN (idler diameter 133-159mm) |

||

|

20 KN (idler diameter> 159 mm) |

||

|

7. |

idler drop test |

All parts and welds shall not be damaged and detached; The axial displacement of the idler after falling shall not be greater than 1.2mm; The idler tube body and the bearing seat shall not be loosened; The rotation resistance coefficient of the falling idler shall not be greater than 1.5 times that before falling. |

When choosing the idler, attention should be paid to its appearance is smooth and clean, without obvious defects, and the performance indicators meet the following requirements.

Table 1

Table 2:

|

Idler diameter (mm) |

Belt speed m/s |

|||||||||

|

0.8 |

1 |

1.25 |

1.6 |

2 |

2.5 |

3.15 |

4 |

5 |

6.5 |

|

|

Idler rotation speed, r / min |

||||||||||

|

89 |

172 |

215 |

268 |

344 |

429 |

537 |

|

|

|

|

|

108 |

142 |

177 |

221 |

283 |

354 |

442 |

557 |

|

|

|

|

133 |

|

144 |

180 |

230 |

287 |

359 |

453 |

575 |

|

|

|

159 |

|

120 |

150 |

192 |

240 |

300 |

379 |

481 |

601 |

|

|

194 |

|

|

123 |

158 |

197 |

246 |

310 |

394 |

492 |

|

|

219 |

|

|

|

|

|

|

275 |

349 |

436 |

567 |

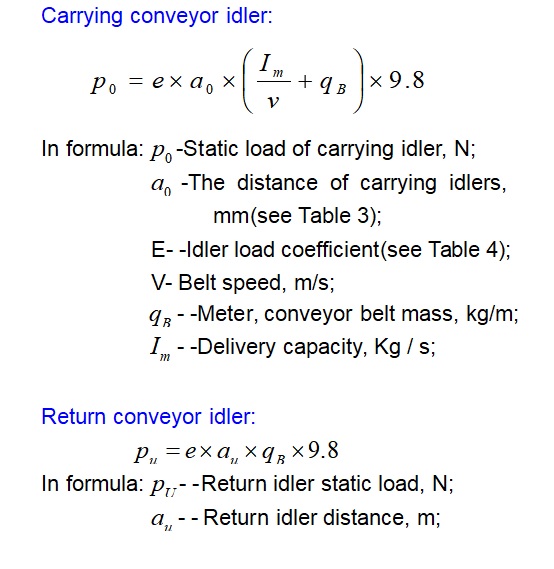

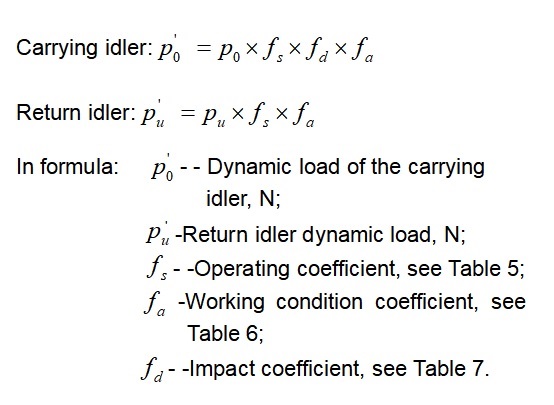

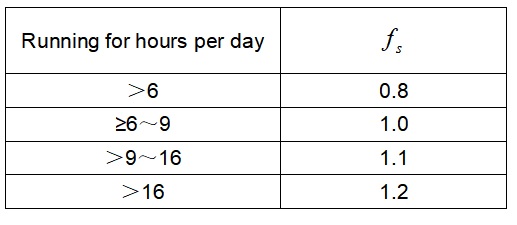

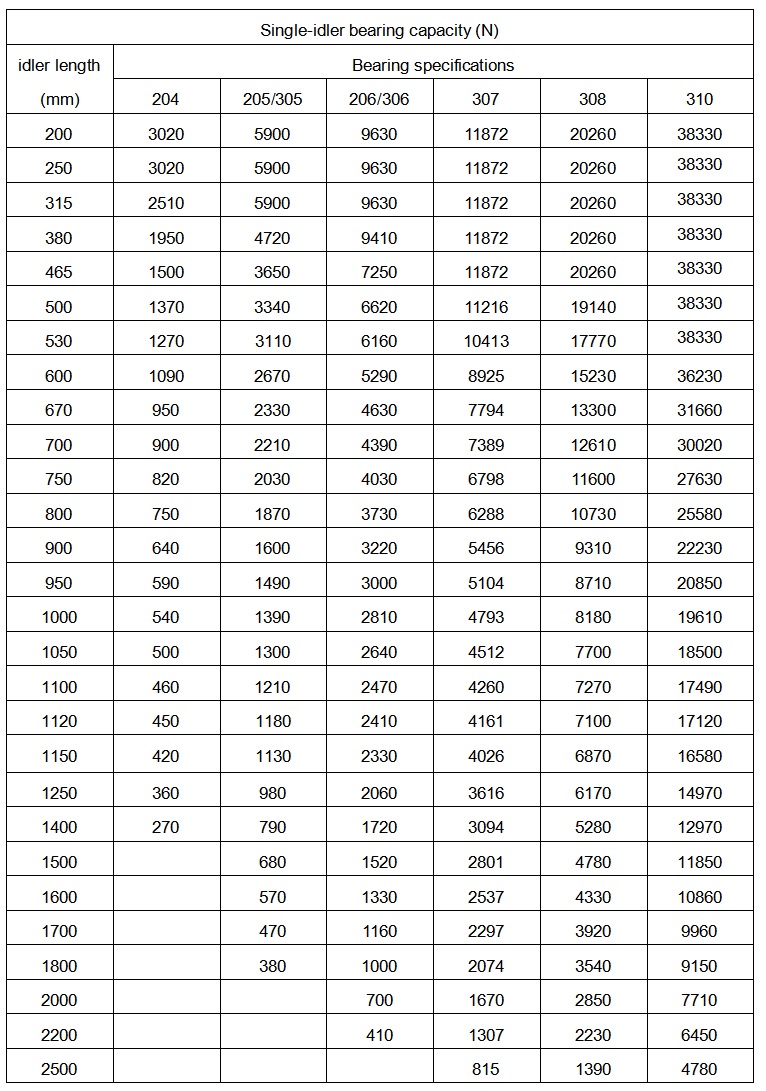

After the calculation, record the larger value of the static load and the dynamic load, and check the conveyor idler bearing capacity (table8) to select the conveyor idler so that the bearing capacity is greater than or equal to the calculated value.

|

loose density Kg/m³ |

Belt width |

|||

|

500 650 |

800 1000 |

1200 1400 |

1600 1800 2000 2200 |

|

|

Idler spacing |

||||

|

≤1600 |

1200 |

1200 |

1200 |

1000 |

|

>1600 |

1000 |

1000 |

1000 |

1000 |

|

Idler Group |

e |

|

One idler |

1 |

|

Two idler |

0.63 |

|

Three idler |

0.8 |

In conclusion, selecting the right conveyor idler is crucial for ensuring the smooth and efficient operation of your conveyor system. By following the guidelines outlined in this comprehensive guide, you can make informed decisions based on factors such as load capacity, belt width, roller material, and environmental conditions. Remember to consider the specific needs and requirements of your application to choose idlers that offer durability, reliability, and optimal performance. With a well-chosen conveyor idler, you can enhance productivity, reduce maintenance costs, and maximize the overall efficiency of your material handling processes.

A Step-by-Step Guide to Selecting the Right Conveyor Idlers 2023

10 basic factors to consider when choosing a suitable conveyor idler

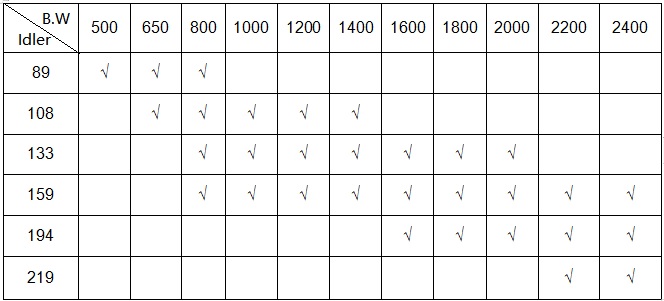

Only one table can help you easily choose the right conveyor idler set (belt width from500~2400mm)

3 key parts that most affect the operating life of conveyor idlers

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China