Conveyor idlers are playing an increasingly important role in modern industries such as coal mines, power plants, ports, and automated packaging lines. Whether it is a dusty factory or mine, or a spotless modern pharmaceutical packaging production line, or the environment is harsh and corrosive In the strong chemical industry, conveyor idler play a key role, once any problem occurs with a few or even one conveyor idler, it will affect the smooth operation of the conveyor line. Serious damage will even cause damage to the conveyor belt and shutdown of the entire belt conveyor line. , so the conveyor idler that meet the technical standards are the key to ensure the smooth operation of the belt conveyor.

So which parts of the conveyor idler will affect the running of the conveyor idler? There are three parts that are very critical:

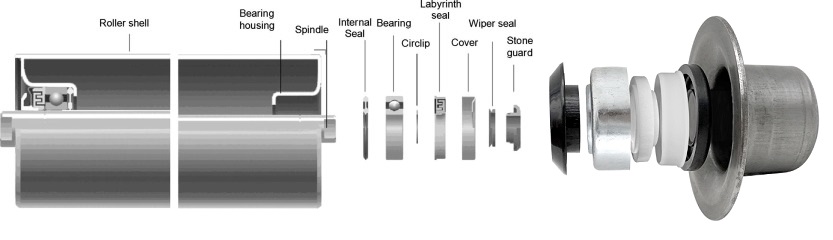

1. Steel pipe: The steel pipe used for the idler, the steel pipe is the main part of the main body of the conveyor idler, and it is also the part that is in contact with the conveyor belt surface, so the quality of the steel pipe for the conveyor idler is very important, a good conveyor idler adopts a special welded straight seam pipe with uniform wall thickness, no grooves or convex marks in the weld seam, good straightness and high roundness, which will make the conveyor idler and the bear house fit perfectly, thereby reducing the radial run-out, increases the operating life of the conveyor idler, generally, the most commonly used steel pipe materials are Q235, ST37-2, AXIS, XC 48

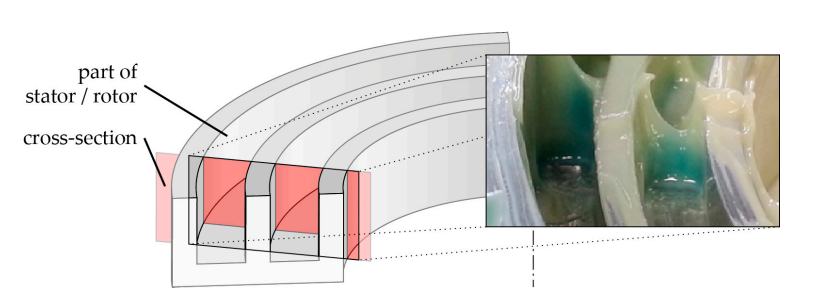

2. Sealing system: The sealing system is a key part of the roller, which plays an important role in protecting the bearings, so the seals must be strictly assembled, generally, the sealing system of the conveyor idler adopts a “labyrinth” type, the structure of this labyrinth sealing system is mature and stable, and the sealing effect is good. During the assembly process of the idler, the sealing cover outside the sealing system cannot be concentric with the bearing seat. There will be a large gap on one side, so that dust and water can easily enter the sealed interior of the conveyor roller, which will cause friction and corrosion to the roller and reduce the life of the roller.

3. The rotation resistance of the conveyor idler: A certain amount of lithium-based grease is added to the bearing and sealing system of the high-quality conveyor idler during assembly, so the rotation resistance of the conveyor idler during the rotation all comes from the adhesion of lithium-based grease in the bearing. when the conveyor idler is in normal use, an appropriate amount of lithium grease is added to lubricate the bearing to prolong its working life, and less or no lithium-based grease will increase the friction between the sealing system and bearing, but too much grease will also make the whole sealing system is in a state of overheating, so it is reasonable that lithium-based grease accounts for 3/4 of the entire sealing system.

If the above three parts meet or even exceed the technical requirements, the service life of the conveyor idler will be greatly extended, so that the entire conveyor line will be in a stable running state.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China