When we receive an inquiry from a customer for the conveyor idler, the first thing we need to confirm with the customer is: what material is the conveyor idler used to transport? So why do we need to confirm this detail with the client? How does this detail affect the selection of conveyor idler bearings?

The conveyor idler is an important part of the belt conveyor system, its stable operation is a necessary condition to ensure the smooth operation of the entire belt conveyor line, any quality problems and selection errors of the conveyor idler will cause the entire conveyor line to drop in efficiency or even shut down, and the bearing is the most important accessory that constitutes the rotating part of the conveyor idler. The correct selection of the bearing is directly related to the normal operation and service life of the conveyor idler.

Since conveyor idlers usually operate in complex outdoor environments, such as high temperature, humidity, cold, dusty and even various acid-base environments, the selection of bearings for conveyor idlers is very important to adapt to various harsh environments and ensure that the conveyor idlers the smooth operation of the conveyor idlers.

Let's take a look at the specific types of conveyor idler bearings that have been applied to the environment.

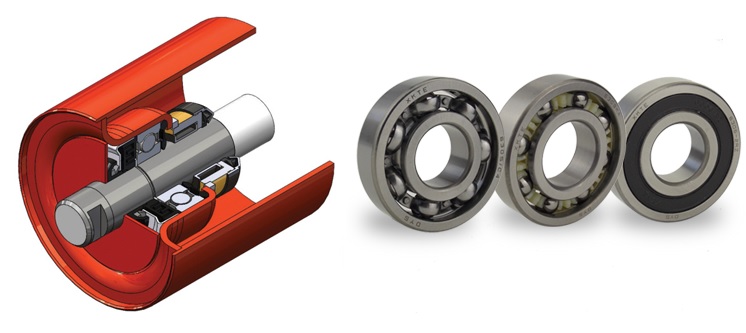

The bearings of conveyor idlers are usually deep groove ball bearings, also known as single row radial ball bearings, which are the most widely used rolling bearings. It is characterized by small frictional resistance and high speed, and can be used on parts that bear radial loads or joint loads that act simultaneously in radial and axial directions. The basic deep groove ball bearing consists of an outer ring, an inner ring, and a set of steel balls and a set of cages. There are two types of deep groove ball bearings: single row and double row, generally, conveyor idlers with a diameter of less than 133mm use single row deep groove bearings.

Deep groove ball bearings are divided into open bearings, metallic cover sealed bearings and rubber cover sealed bearings

1. Open deep groove ball bearings are suitable for high-speed or even extremely high-speed operation, this type of bearing has a small friction coefficient, high limit speed, and low cost,it can be filled with lubricating oil many times to prolong the service life of the conveyor idler. However, due to the open type, the bearing has no sealing design, so it has high requirements on the operating environment, the conveyor idler using this bearing is suitable for environments with moderate temperature, no dust, and moderate humidity, such as indoor food transportation, agricultural product processing, packaging workshops, etc.

2. Open bearings are divided into KA or TN nylon cage bearings

The nylon cage is characterized by a good combination of strength and elasticity, nylon has good sliding performance on the lubricated steel surface and produces little friction, so the heat and wear in the bearing are very low. The low-density material means that the cage has very little inertia. Nylon cages have excellent running characteristics in the absence of lubricant, allowing the bearing to continue to operate for a period of time without quickly developing seizure and further damage. This type of bearing is mostly used in mine conveying machinery, which can effectively prevent static electricity caused by bearing rolling.

3. Steel cover sealed bearing (model suffix: ZZ&2Z)

Because the bearing is sealed with a steel cover, it can effectively prevent dust and environmental impurities from entering, thereby effectively protecting the bearing from being stuck due to friction caused by impurities inside the bearing, and this bearing has high speed and high temperature resistance. The disadvantage is that the protection effect on liquids is not good, such as water, sediment, etc., so the conveyor idlers with steel cover sealed bearings are suitable for operation in dry, high temperature, high speed environments, such as outdoor mines, cement plants, steel plants, etc.

4. Rubber cover sealed bearing (model suffix: 2RS)

This kind of bearing adopts contact rubber sealing ring (NBR), this kind of sealing ring has excellent effects of preventing dust, water and moisture, and can also prevent the leakage of lubricating oil. However, due to the sealing lip, the friction and friction torque are large, so the speed of the conveyor idler using this kind of bearing should not be too high, at the same time, due to the limitation of the characteristics of the rubber itself, the ideal working temperature of the bearing can only be around 120 °C.

After the bearing is selected well, the choice of lubricating grease in the conveyor idler bearing and the labyrinth seal is also very important, such as using cold-resistant, high-temperature-resistant and different viscosity models to make sure conveyor idler adapt to the use requirements in different environments.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China