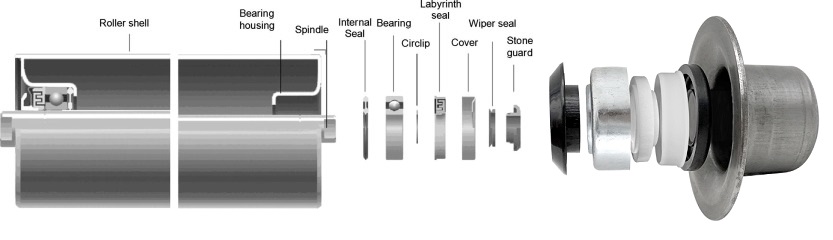

The seal of conveyor accessory conveyor idlers is mainly divided into labyrinth seal (non-contact) structure and lip seal (contact) structure, both of which have advantages and disadvantages.

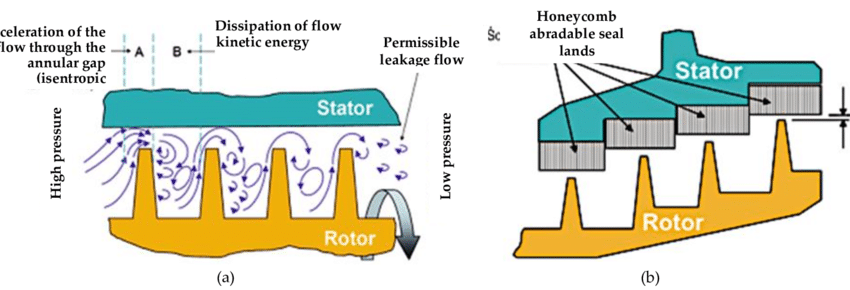

The labyrinth seal is composed of several sets of ring-shaped sealing teeth. A set of throttling gaps and expansion cavities are formed between each ring. When gas or dirt flows through the gaps of each ring, the throttling effect is generated due to viscous friction. Slow down the flow rate and reduce the leakage. When the gas passes through the tooth tip gaps of each ring, a series of isenthalpy thermodynamic processes will be generated, which further reduces the flow rate and flow rate and enhances the sealing effect. Pushed by the pressure difference or external force, the dirt enters the cavity through the top gap, and the sudden expansion will generate a violent vortex. Most of the dirt can be converted into heat energy and absorbed by the airflow or impurities in the chamber, making the The values of K for similar gaps are approximately equal. A small part of the airflow remains, passing through the gap at the top of the next stage at a residual speed to continue to reduce the flow rate and flow, repeating the above process, the residual velocity of the dirt or airflow is very low, and the leakage is very small, which plays a sealing role.

However, when the conveyor idler is running at high speed, due to the existence of internal friction, heat will inevitably be generated, causing the temperature in the sealing cavity of the bearing to rise, and the grease will vaporize as the temperature rises. After the conveyor idler stops running, as the temperature drops, the air pressure in the bearing seal chamber drops, resulting in an air suction process. Along with the air suction process, a large amount of dust particles enter the bearing seal chamber, resulting in the pollution and drying of the grease, thus speeding up the bearing process. wear and tear. After the grease is gradually reduced to a certain extent with the continuous occurrence of vaporization, the bearing will continue to run in a dry friction state, which will inevitably aggravate the wear of the bearing and greatly shorten the service life of the conveyor conveyor idler. In short, the labyrinth seal structure has the following characteristics:

1. The labyrinth seal is a non-contact seal, no solid phase friction, no lubrication, suitable for high temperature, high pressure, high speed and large size sealing conditions.

2. The labyrinth seal works reliably, with low rotation resistance and power consumption, easy maintenance and long service life.

3. The labyrinth seal has breathing problems, and the leakage is obvious. Increasing the number of labyrinths and using auxiliary sealing methods such as air extraction can reduce the leakage, making it difficult to achieve sealing.

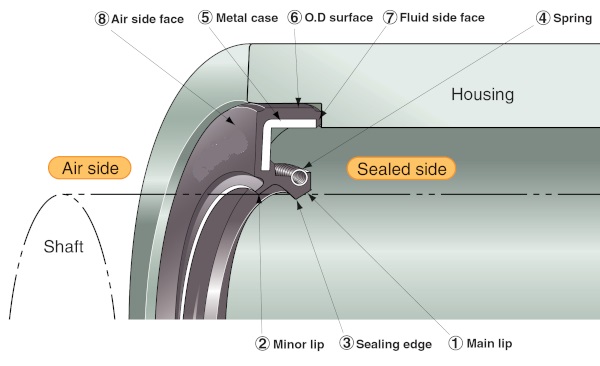

The contact seal used by the conveyor idler is generally a contact elastomer seal. According to the working principle, it can be two types of extrusion seal and lip seal, such as O-ring, L-ring, etc., and the materials are rubber, plastic, leather, etc. Extrusion-type seals rely on the pre-compression elastic deformation imposed by the filling groove to block dirt or moisture from entering the channel to obtain a sealing effect. Under the action of the medium pressure, the contact pressure of the contact surface increases, which can further improve the sealing effect, but also Correspondingly increased rotational resistance. The lip seal also relies on the pre-compression elastic deformation of the groove to block the leakage channel, and under the pressure of the medium, the lip is further pressed against the pair to increase the blocking and sealing effect.

The leakage of a properly designed contact seal is not large, lower than that of the contact seal, and empirical data confirms that the leakage has little relationship with the type of sealing ring. In short, the sealing effect of the contact sealing structure is better, but when the material selection is inappropriate or the structural design is unreasonable, its rotation resistance is larger than that of the labyrinth sealing structure. In the case of large temperature and pressure differences and uneven distribution, the sealing The elastic deformation of the lip is also inconsistent, resulting in poor sealing effect.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China