In recent years, with the large-scale and modernization of mining enterprises in China, large conveyor idlers have become the primary means of transportation in large inclined shaft mines. Conveyor belt misalignment in conveyor systems often leads to equipment downtime, material spillage, frame blockage, belt edge tearing, wear, and other faults, significantly affecting equipment usage and lifespan, and reducing transportation efficiency. Therefore, it should receive sufficient attention during design and installation. This article provides a mechanical analysis of the impact of reasonable conveyor idler placement on the operation of conveyor belts. This article focuses on the different installation methods of conveyor idlers in conveyor systems and their effects during operation.

Analysis of the Forces on Conveyor Idlers during Conveyor Operation

The installation methods for conveyor idler sets can be categorized into three types based on the angle with respect to the conveyor's running direction: vertical conveyor idler set installation, forward-leaning conveyor idler set installation, and backward-leaning conveyor idler set installation.

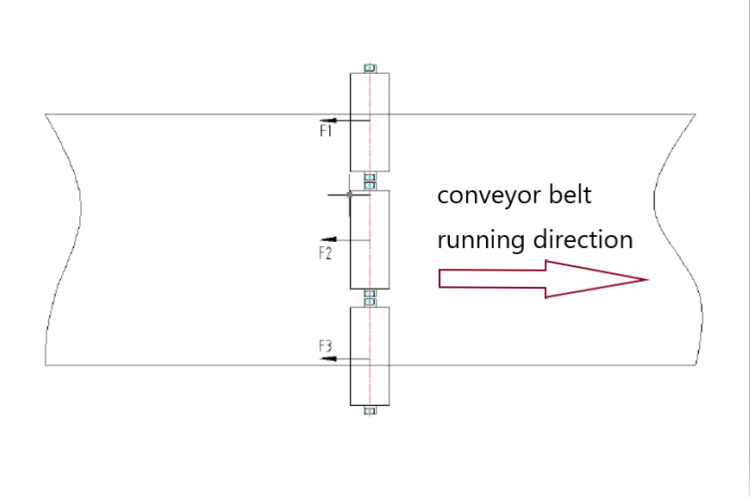

1.1 Vertical Conveyor Idler Set Installation:

In this installation method, the conveyor idlers are positioned vertically to the centerline of the conveyor belt, as shown in Figure 1.

This installation provides frictional resistance forces F1, F2, and F3 in the direction opposite to the traction force generated by the conveyor belt. In an ideal state (assuming uniform material distribution on the conveyor belt and no conveyor belt misalignment), F1 and F3 are equal. In this scenario, the conveyor belt experiences frictional resistance in the opposite direction of its movement, and there is no lateral force acting on the belt. Therefore, the conveyor belt does not experience lateral misalignment (i.e., belt misalignment) in this configuration.

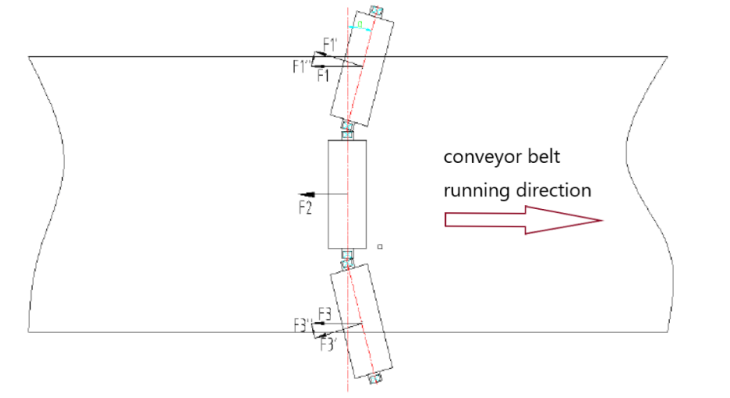

1.2 Forward-Leaning Conveyor Idler Set Installation:

In this installation method, the conveyor idlers on both sides are inclined forward at a certain angle (usually 1.5° to 2.0°) along the direction of conveyor operation, as shown in Figure 2.

This installation is similar to the vertical conveyor idler installation, but it includes additional forces (F1' and F3') due to the friction, which causes the conveyor belt to self-adjust when misaligned. When the belt moves away from the centerline, the forces on one side increase, causing the belt to shift back to the center. This self-adjustment helps prevent conveyor belt misalignment, but it increases conveyor belt wear due to additional sliding friction. Forward-leaning conveyor idlers are suitable for one-way belt operation.

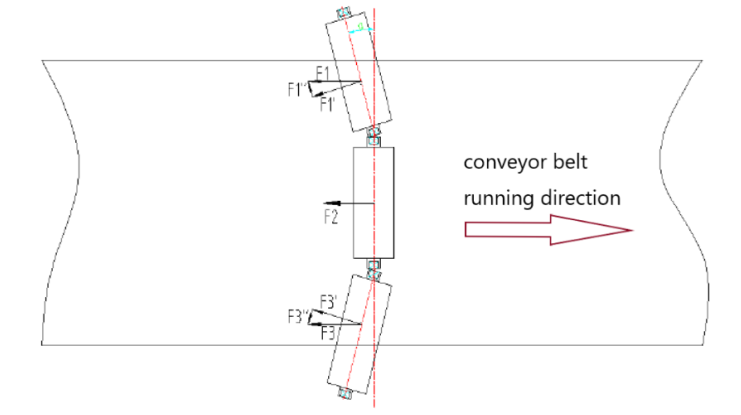

1.3 Backward-Leaning Conveyor Idler Set Installation:

In this installation method, the conveyor idlers on both sides are inclined backward in the direction opposite to the conveyor operation, as shown in Figure 3.

This installation is similar to the standard conveyor idler installation, but the backward inclination of the side conveyor idlers helps reduce friction along the entire length of the conveyor belt, resulting in lower resistance. However, this installation has a significant drawback: when the belt moves away from the centerline, the forces on one side increase, causing the belt to continue misaligning. This makes it unsuitable for practical use.

Conclusion:

Backward-leaning conveyor idler installation results in the lowest running resistance but exacerbates conveyor belt misalignment when it occurs. Vertical conveyor idler installation has higher running resistance than backward-leaning installation but does not affect conveyor belt misalignment and has no self-adjustment capability. Forward-leaning conveyor idler installation has the highest running resistance but can self-adjust in case of conveyor belt misalignment, ensuring smooth conveyor belt operation. Therefore, when arranging conveyor idler sets, it is important to choose the installation method that balances benefits and drawbacks. Ultimately, the goal is to ensure the scientific and rational operation of the conveyor belt, which is of great significance for mine production.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China