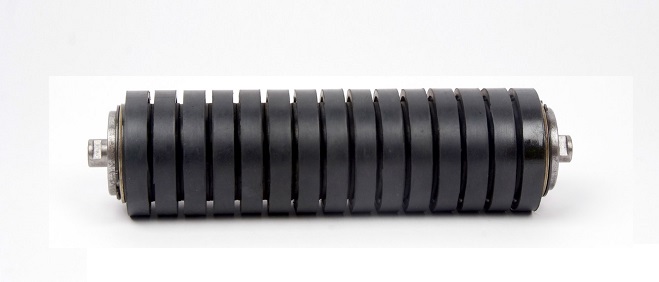

The working principle of the impact idler is: when the material falls onto the surface of the conveyor belt, the impact idler uses the elasticity of its own strong rubber to reduce the hard impact of the material on the conveyor belt, and effectively protect the conveyor belt and the carrier idler The service life of the conveyor belt is extended, and the production cost is reduced.

In the installation of impact idlers, the first is to increase the density of the installation; the second is to frequently check and replace damaged idlers in time. It is recommended to install a impact bed for the conveyor belt with large blank drop, and replace the impact idler with a impact bed. According to the characteristics of the impact idler, some points to be noted in the purchase are: the radial runout of the idler, the flexibility of the idler, the amount of axial movement, the dustproof performance of the idler, the waterproof performance, the axial bearing performance of the idler, The anti-impact performance of idlers.

1. What protection functions does the impact idler have?

(1) Impact idler temperature protection: When the temperature of the belt conveyor idler and the conveyor belt friction exceeds the limit, the detection device installed closely to the idler sends out an over-temperature signal. After the receiver receives the signal, it extends for 3 seconds to make the execution Part of the action, cut off the power supply of the motor, the conveyor automatically stops, which plays a role in temperature protection.

(2) Speed protection of idler group: if the conveyor fails, such as motor burnout, mechanical transmission part damage, belt or chain breakage, belt slippage, etc., the magnetic control in the accident sensor SG installed on the driven part of the conveyor The switch cannot be closed or closed at normal speed. At this time, after the corresponding extended time according to the inverse time limit characteristic, the speed protection circuit works to make the execution part of the action and cut off the power supply of the motor to avoid the accident from expanding.

(3) Coal level protection of impact idler coal bunker: There are two high and low coal level electrodes in the coal bunker. When the coal bunker can not put coal because of no empty car, the coal level will gradually increase. When the coal level rises to the high level electrode, The coal level protection action starts from the first belt conveyor, and each conveyor stops in sequence due to the coal piled at the end of the machine.

2. What factors influence the use effect of the impact idler?

(1) The coaxiality of the idler shaft is poor: due to factors such as wear of the tire during the production of the cold-drawn optical axis, the dimensional accuracy is unstable, and there is often a phenomenon of exceeding the standard. In addition, it is easy to cause bending during transportation, which makes the idler shaft Because of the poor coaxiality, the bearing clearances installed at both ends of the idler shaft are not guaranteed, so the rotation resistance of the idler increases, which affects the service life of the idler of the conveyor belt.

(2) Poor coaxiality of the bearing housing: the idler bearing is a stamping part, and the joint with the barrel is not processed, and the bearing housing is directly welded on the barrel. The problem of non-round bearing seat or unequal end face at the place where it cooperates with the barrel skin during stamping is likely to cause different shafts at both ends of the bearing seat after welding with the barrel skin, resulting in reduced bearing clearance, increased rotational resistance, and inflexible rotation.

(3) The sealing effect is not good: its waterproof effect is poor, and the production condition of the underground belt conveyor is that the dust is large and the water is used to remove dust at the same time, so the seal used by the idler needs to have good dustproof and waterproof effects. If the water in the idler group will corrode the bearing, the dust will damage the bearing, which will affect the service life of the idler.

I believe that many companies are troubled by the damage of the impact idler. The new idler will not be used for a long time and it will break. Many users cannot find the reason. In fact, sometimes it has little to do with the quality of the idler. The original role of the self-aligning bracket Yes, it is used for self-alignment when the material on the tape is off-load. However, due to inadequate installation and debugging experience, many belt conveyors make the tape become "congenital" deviation, all rely on the friction between the self-aligning support idler and the tape to correct the deviation. This phenomenon not only caused an increase in power loss after the increase in running resistance, but also caused rapid wear of the idler and tape at the same time, and also seriously affected the life of the drum, reducer, motor and other components. There are still many companies whose tapes run seriously. They simply fix the self-aligning bracket with a wire to a large angle, causing the idler body to be worn through in about a month. The solution is very simple: readjust the belt conveyor to achieve the state that the self-aligning bracket does not work when it is running without load. It is also possible to install the flange idler on the fixed bracket without installing the self-aligning bracket.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China