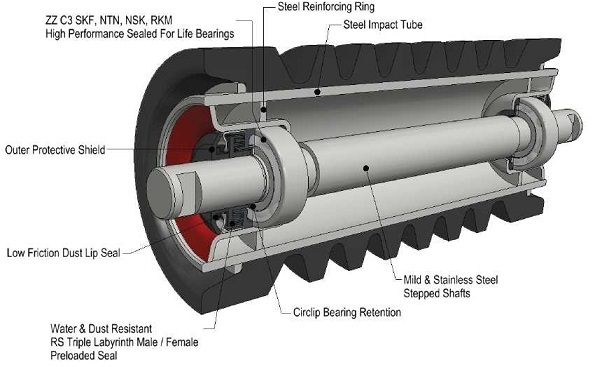

Impact idler, the impact idler is used at the receiving place of the belt conveyor to slow down the impact of the blanking on the conveyor belt. It is a type of idler mainly developed for corrosive environments such as coal washing plants, coking plants, and chemical plants. , Its toughness is more than 10 times that of ordinary metals, its life is five times that of traditional idlers, corrosion resistance, flame retardant, antistatic, light weight, etc. It is widely used in mining. The polymer material specially used for the roller body, its mechanical properties are similar to bronze, it has good wear resistance, and it has good self-lubricating properties, which does not damage the conveyor belt.

The impact idler is light in weight and has small rotational inertia. The special polymer material for rollers is light in weight, and its specific gravity is one-seventh of that of steel. The rollers made of this material are about one-half of the weight of ordinary rollers, and have small rotational inertia. low friction

impact idler standard diameter parameters

According to the conveyor industry standard, there are 4 standard types of impact idler diameters for belt conveyors with a width of 500mm-1400mm, namely: φ89mm, φ108mm, φ133mm, φ159mm.

With the emergence of large belt conveyors, the diameter of impact idlers also tends to increase.

impact idler installation and purchase

In terms of installation of impact idlers, one is to increase the density of installation; the other is to check frequently and replace damaged idlers in time. It is recommended to install a impact air lock for the conveyor belt with a large blanking drop, and replace the impact idler with a impact bed. In terms of purchasing, according to the characteristics of the impact idler, the following points are put forward: the radial runout of the idler, the flexibility of the idler, the axial movement, the dustproof performance of the idler, the waterproof performance, the axial bearing performance of the idler, Roller impact resistance, etc.

Protection of impact rollers

(1) impact roller temperature protection

When the friction between the roller and the belt of the belt conveyor causes the temperature to exceed the limit, the detection device installed close to the roller will send an over-temperature signal. After the receiver receives the signal, after a delay of 3s, it will execute some actions, cut off the power supply of the motor, and the conveyor will automatically Stop, play a role in temperature protection.

(2) Speed protection of impact idler set

If the conveyor fails, such as the motor burns, the mechanical transmission part is damaged, the conveyor belt or chain is broken, the belt slips, etc., the magnetic control switch in the accident sensor SG installed on the passive part of the conveyor cannot be closed or cannot be operated at normal speed. When it is closed, the control system will act according to the inverse time characteristic and after a certain delay, the speed protection circuit will work to make the execution part of the action cut off the power supply of the motor to avoid the expansion of the accident.

(3) Coal level protection of impact roller coal bunker

There are two high and low coal level electrodes in the coal bunker. When the coal bunker cannot discharge coal because there is no empty vehicle, the coal level will gradually increase. When the coal level rises to the high level electrode, the coal level protection action starts from the first belt conveyor. , each conveyor will stop in turn due to the coal pile at the tail.

The reason for the damage of the impact idler

1. Due to the large dust at the blanking point, when the sealing performance of the impact idler is poor, it is very easy to be polluted and cause damage to the bearing;

2. The impact apron is basically made of recycled rubber, not only has poor elasticity, but also has poor wear resistance, tear resistance, and aging resistance. The impact force is small, and the service life is only about 1 year. , it will break and fall off within ten days, causing serious damage to the conveyor belt.

Influencing factors of impact roller resistance

1) The diameter of the idler, the quality of the rotating part, the installation quality, the groove angle, the lubrication condition and the distance between the idlers, and the transmission roller.

2) The thickness, rubber hardness and tension of the upper and lower covering rubber of the conveyor belt, grooved idler.

3) Belt speed, environment and temperature, properties of conveyed materials, etc., impact idler.

Correct selection of impact rollers for belt conveyors

The application of impact idler in belt conveyor is very important, it supports the conveyor belt and bears the weight of the material. It can be seen that the role of the idler is very important. Therefore, the structural performance of the impact roller is more important.

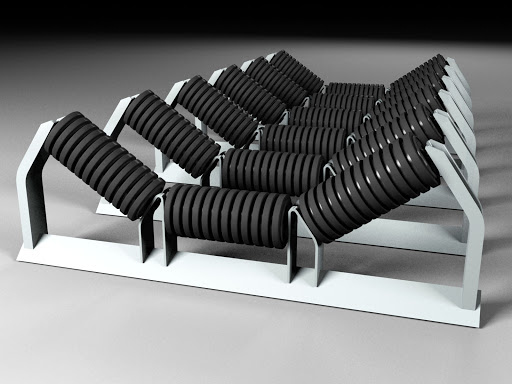

The special polymer material for impact rollers is light in weight, and its specific gravity is one-seventh of that of steel. The rollers made of this material are about one-half of the weight of ordinary roller accessories, and have small rotational inertia. The friction between the belts is small, effectively reducing the friction between them. Reducing the distance between idlers can reduce the simulated friction coefficient, but the total resistance value will increase. Do not increase the density of idlers in the general bearing section except to protect the conveyor belt at the unloading point. In addition, the rubber ring of the impact idler is wear-resistant and has a long service life. The special polymer material for the roller body, its continuous performance is similar to that of bronze, has good wear resistance, and has good self-lubricating performance, which does not damage the belt. There are also many types of impact rollers, such as spring plate type, impact ring type, strong impact type, and so on. So be sure to choose the right one. When selecting the idler, pay attention to the radial runout of the idler, the flexibility of the idler, and the amount of axial movement. In places where the material drop is more than six meters, we need to use impact rollers, which can not only effectively reduce the impact and wear of the conveyor belt material, but also prevent the conveyor belt from being torn by hard objects.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China