What is a impact idler and applicable guidance

1. Overview

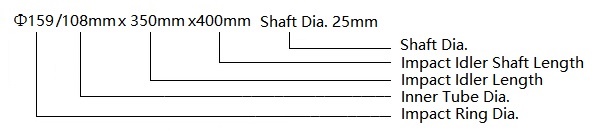

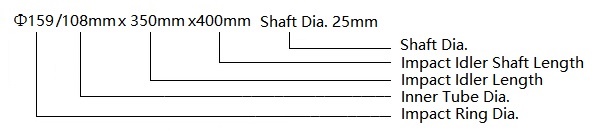

Impact conveyor idlers are installed at the tail of the conveyor to support the conveyor belt and the material it carries, reducing the impact on the conveyor belt. The technical parameters of impact conveyor idlers vary with the width of the conveyor belt.The specifications and models of general impact conveyor idler are as follows:

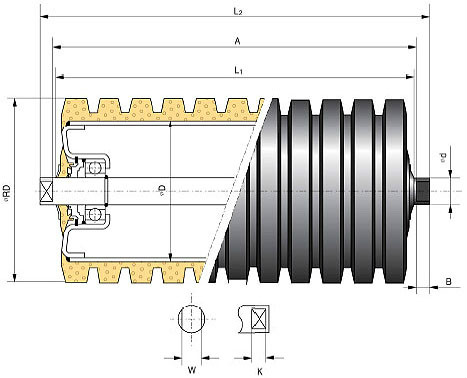

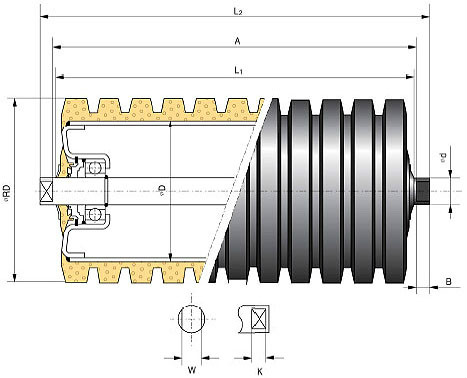

2. Structure of Impact Conveyor Idlers:

2. Structure of Impact Conveyor Idlers:

The structure of impact conveyor idlers is shown in the diagram below:

3. Main Technical Parameters and Performance of Impact Conveyor Idlers:

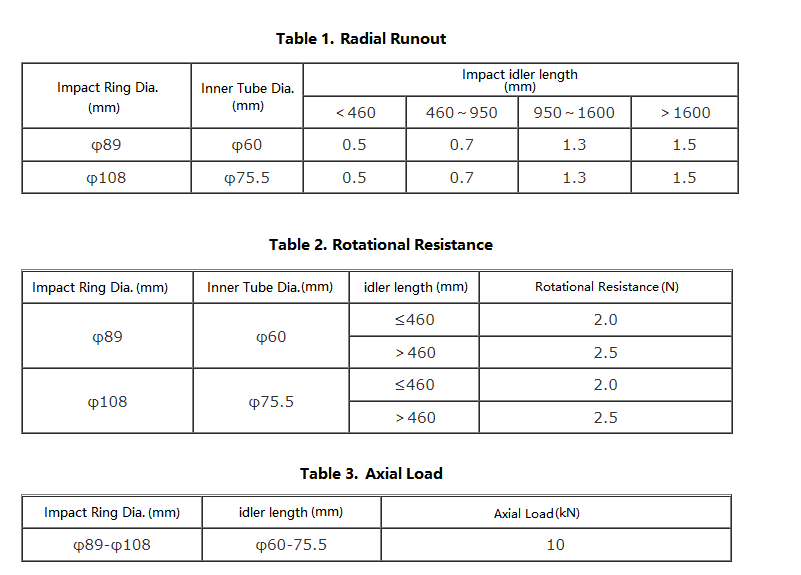

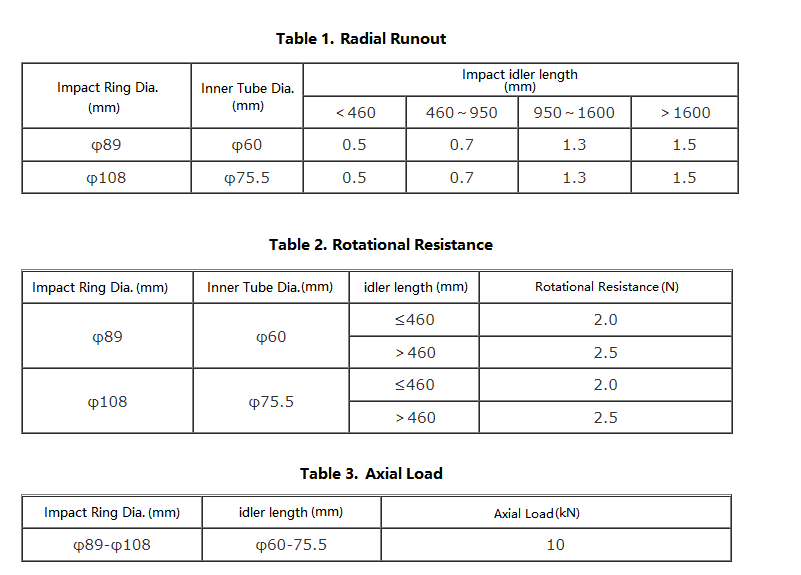

Radial Runout: The radial runout shall not exceed the defined value in Table 1.

Axial Movement: Under a 500N axial load, the axial movement of the idler shaft shall be less than 1.2mm.

Rotational Resistance: When subjected to a 250N pressure, the rotational resistance of the idler at an outer circle linear velocity of 2.0m/s shall be less than the defined value in Table 2.

Drop Strength: After horizontal and vertical drop tests, all components and welds of the idler shall have no damage or detachment. The axial displacement of the idler shaft shall not exceed 1.2mm, and there shall be no loosening between the idler tube and the bearing seat. Furthermore, after drop testing, the rotational resistance shall be less than 1.5 times the specified value in Table 2.

Axial Load: After applying the axial load specified in Table 3 to the idler, there shall be no detachment between the idler shaft (including the bearing seat and sealing device) and the idler tube.

Immersion Seal Performance: After rotating at a speed of 1450r/min in clear water for 24 hours, the idler's water intake shall not exceed 150g.

Water Spraying Seal Performance: After operating at a speed of 1450r/min for 120 hours, the idler's water intake shall not exceed 250g.

Service Life: The service life shall not be less than 20,000 hours.

The rubber ring in the idler shall meet the safety requirements of MT113.

4. Installation and Adjustment of Impact Conveyor Idlers:

Installation: Hang the idler on the idler frame already installed on the belt conveyor, and attach the corresponding connecting parts. The upper surface of the idler should be in the same plane (horizontal or inclined) or on a common radius arc (concave or convex segment of the conveyor). The height difference between adjacent three sets of idlers should not exceed 2mm for fixed belt conveyors and not exceed 3mm for telescopic and suspended belt conveyors. For troughing impact idlers, assemble three idlers into a chain using hinge plates and clevis pins before installation, and then install each chain of idlers onto the conveyor.

5. Use and Operation of Impact Conveyor Idlers:

It is essential to maintain a clean working environment for the idlers. After the drive device is turned off, perform regular inspections, adjustments, maintenance, and cleaning of the idlers.

During conveyor belt operation, the edges of the belt should not exceed the edges of the idler rolls.

6. Environmental Conditions for Use:

Ambient temperature: -10°C to +40°C.

The composition of underground air should comply with the provisions of Article 100 of the "Coal Mine Safety Regulations" (2004 edition).

The working environment may involve exposure to water.

The idlers should be able to withstand normal collision conditions during handling and installation.

9. Maintenance, Repair, and Warnings:

Regularly clean the idlers to keep the roller body clean.

Periodically inspect the idlers, and if any idler is not rotating smoothly, it should be immediately removed and replaced.