At present, the belt conveyor system commonly use steel conveyor idlers, which have high energy consumption, large running resistance coefficient, and heavy weight. Moreover, ordinary steel conveyor idlers are not suitable for noise reduction, mines with high electrostatic requirements, coking plants, chemical enterprises and other special industries with strong corrosive, in this case, UHMWPE and HDPED conveyor idlers came into being.

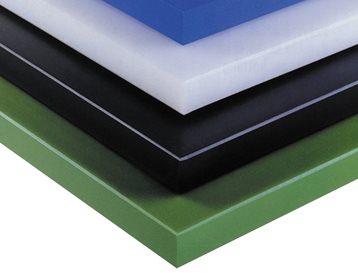

The shells of UHMWPE and HDPE conveyor idlers are made of high molecular weight polyethylene. The molecular weight of HDPE is 2w~30w, and the molecular weight of UHMW-PE is 4.5 million to 12 million, which conforms to the American ASTM 4020 standard. Compared with traditional (existing) carbon steel, nylon and ceramic conveyor idlers, it has excellent wear resistance, and the wear resistance of UHMW-PE material is 7 times that of traditional carbon steel.

In addition to excellent wear resistance, HDPE/UHMW-PE materials have the following characteristics:

1. Corrosion resistance, strong chemical resistance

HDPE/UHMW-PE material has strong resistance to wear and corrosion of main aggressive elements (including chemical reagents), except for some strong acids that are slightly corroded at high temperature, in other lye and acid solutions, it can be used in < Use at a concentration of 80 °C; in a concentration of <75%, the performance of nitric acid with a concentration of <20% is stable, and the performance of seawater and liquid detergents is also stable. It is immersed in 80 organic solvents at 20 °C and 80 °C for 30 days. There is no abnormality in appearance. phenomenon, and other physical properties are almost unchanged

2. HDPE/UHMW-PE conveyor idlers are belt friendly and can ensure lower belt wear

Due to the waxy nature of HDPE/UHMW-PE, the coefficient of friction (196N, 2 hours) is only 0.219MN/m, and the self-lubricity is very good, especially in harsh environments, with good surface non-sticking, no fouling, this feature prevents any conveyed material from adhering to the surface of the idler while the conveyor belt is running, and will not cause wear and scratches to the conveyor belt even when individual conveyor idlers stop running.

3. Impact resistance and impact energy absorption

HDPE/UHMW-PE has the highest impact strength among all engineering plastics, about 3 times that of nylon, 2 times that of PC, and 5 times that of ABS, which can withstand repeated impact,

4. Light weight and energy saving

The weight of HDPE/UHMW-PE drum is only one third lighter than that of steel drum, and the specific gravity of ultra-high molecular weight polyethylene is very light, only about 0.94, which is 1/8 of carbon steel. As an idler, the installation and replacement are easy and convenient, and the operation is noiseless, which reduces the work intensity and purifies the working environment.

5. Long operating life

The operating life of HDPE/UHMW-PE is about 1/3 longer than that of ordinary steel conveyor idlers. Longer operating life means less maintenance downtime, lower maintenance costs, and higher transportation efficiency.

HDPE/UHMW-PE conveyor idlers have so many advantages, it seems that replacing ordinary steel conveyor idlers is an inevitable trend in the future, is that true? Let's take a look at the shortcomings of HDPE/UHMW-PE conveyor idlers

1. HDPE/UHMW-PE conveyor idlers have low heat resistance (thermal deformation temperature), outer surface hardness, rigidity, and creep resistance than steel conveyor idlers, and the structure will expand to varying degrees in high temperature environments, resulting in The sealing performance is reduced, thereby affecting the life of the idler.

2. In addition, HDPE/UHMW-PE has poor fluidity, extremely high viscosity in molten state, and is a rubber-like high-viscosity elastomer. If the temperature of the transported material is too high, even the material with fire (such as coke), it will directly damage the surface of the conveyor idler, so the HDPE/UHMW-PE conveyor idler is not suitable for use in the ultra-high temperature environment.

3. HDPE/UHMW-PE conveyor idlers are sensitive to stress or cracking. If the idler encounters irregular sharp and heavy material impact, it will face the risk of local cracking.

4. Since the material of HDPE/UHMW-PE cannot be welded, the overall structure of the idler is not as stable as that of ordinary steel idlers, and the idler structure will be loose after long-term operation

5. The most important thing is that the cost of HDPE/UHMW-PE is about 25%-40% higher than that of steel conveyor idlers, which is unbearable for ordinary enterprises.

To sum up, HDPE/UHMW-PE and steel conveyor idlers have their own advantages and disadvantages, which can complement each other. In a considerable period of time in the future, steel conveyor idlers will still be popular due to their stable structure and excellent cost performance. will be the user's first choice

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China