The role of the conveyor idler is to support the weight of the conveyor belt and the material, and it is an important part of the belt conveyor. Since the conveyor idler generates more than 70% of the resistance of the entire conveyor line, the conveyor idler is flexible and reliable, reducing the distance between the conveyor belt and the conveyor idler. Friction is very important. Let's take a look at the structure of rollers with the most widely used three diameters (89/108/133mm) through drawings.

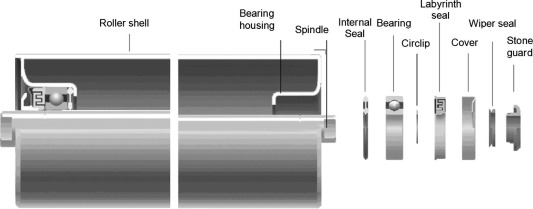

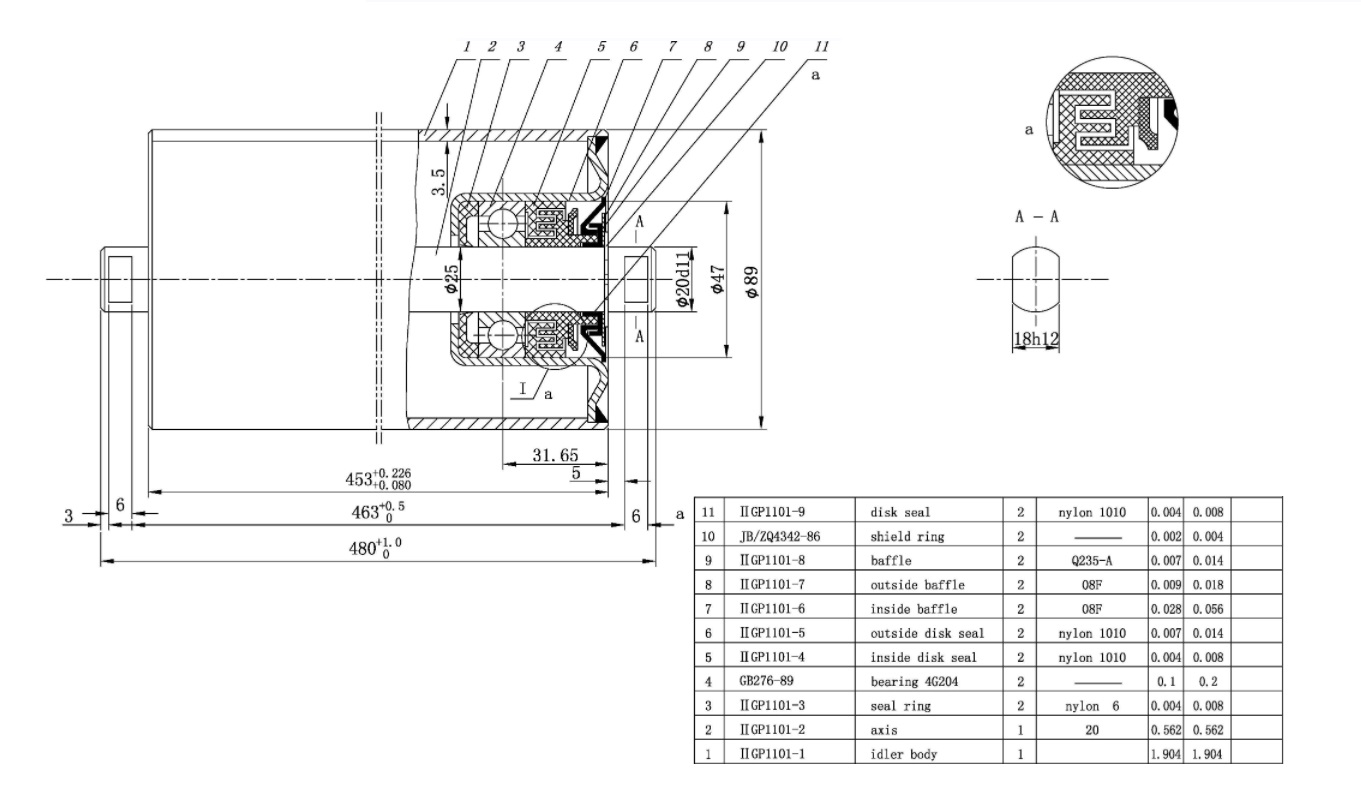

From the drawing, the conveyor idler is mainly composed of cylinder, main shaft, bearing house, retaining ring, sealing structure, bearing house and other structures. Its waterproof and dust-proof, the accuracy of the bearing positions at both ends, the radial run-out of the outer circle, the moment of inertia, anti-corrosion and rust prevention, wear resistance and other comprehensive properties determine the operating state of the belt conveyor to a large extent.

The conveyor idler steel pipe adopts a special straight seam welded pipe for conveyor idlers, and the roundness is controlled within a special tolerance range. Shafts are manufactured from cold drawn steel machined to standard tolerances. The bearing house is stamped from cold rolled steel plate. The sh20 conveyor idler shell and bearing house are welded together by an automatic welding manipulator (we can clearly see the identification of the welding seam from the drawing of the conveyor idler), forming a high-strength overall structure.

The conveyor idler roller bearing adopts the well-known brand's large clearance deep groove ball double-sealed bearing, (6 on the drawing), so that the conveyor idler has an ideal static balance and dynamic balance. The design of the roller sealing material can effectively prevent the erosion of impurities, water and air on the inside of the roller. The light-drawn shaft and the double-layer labyrinth sealing structure (5 on the drawing), and the grease is injected into the sealing cavity to form a good anti-corrosion Dust and waterproof performance, this sealing system has the characteristics of high precision, good sealing, light weight and long service life. Because this sealing system is mature and stable, it is the commonly used conveyor idler sealing method in the world.

The above process makes the roller light in weight and small in radial run-out, which greatly reduces the operating resistance coefficient and moment of inertia, and has a service life of more than 30,000 hours. It can be used in long-distance, high-power conveyors and various polluted environments. stable operation.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China