The conveyor idler is an important part of the belt conveyor, with many types and large quantities. It accounts for 35% of the total cost of a conveyor and generates more than 70% resistance, so the quality of the idlers is especially important.

The role of the conveyor idler is to support the conveyor belt and the weight of the material. The conveyoridler operation must be flexible and reliable. The function is to support the belt, reduce the running resistance of the belt, and make the verticality of the belt not exceed a certain limit to ensure that the belt runs smoothly. Reducing the friction between the conveyor belt and the supporting idlers plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor. Although the conveyor idler is a small part in the belt conveyor and the structure is not complicated, it is not easy to make a high-quality idler.

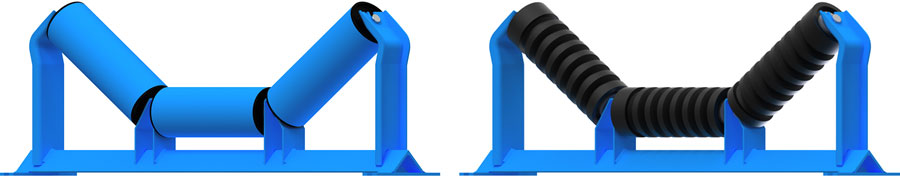

Basic types of conveyor idlers:

(1) The conveyor idler is classified into self-aligning idler, impact idler, troughing idler, and parallel idler according to its purpose. The function of the self-aligning conveyor idler is to correct the deviation of conveyor belt. Usually, the rotary trough-shaped self-aligning idler is installed on the heavy load section of the conveyor, and the parallel self-aligning conveyor idler is installed on the idle section. The impact idler is applied to the tailstock according to the actual situation. When receiving the material, it can reduce the impact of the material on the conveyor belt, which is beneficial to the service life of the long conveyor belt. The trough conveyor idler is generally composed of two side idlers and a flat conveyor idler. The trough angle is generally 30 degrees. For a detachable belt conveyor, the three idlers of the trough idler are hinged to each other, so Called articulated idler. The parallel idler is generally a long roll, which is called the lower idler because it is installed at the lower end under pressure.

(2) The conveyor idlers are divided into two types: steel and plastic idlers. There are three types of idler bearing housings: cast iron, steel stamping, and phenolic plastic.

Conveyor Idler group

The conveyor idlers are sealed with steel and plastic. They are sealed with grease inside. The quality of the idlers directly affects the power consumption of the belt conveyor and the life of the belt. Therefore, the dustproof seal is reliable and the lubrication is important.

There are five other criteria for judging the quality of the conveyor idlers:

1. Dust-proof performance of conveyor idler;

2. Waterproof performance of conveyor idler;

3. Axial bearing performance of conveyor idlers;

4. Impact resistance of conveyor idler;

5. Service life of conveyor idler.

Classification of conveyor idlers:

1. Divided into rubber idler, ceramic idler, nylon idler and insulation idler according to material.

2. There are mainly troughing conveyor idler groups, various types of parallel idler groups, various self-aligning idler groups, and various impact idler groups.

(1) Slotted conveyor idlers include common type idlers, forward type idlers, quick-change bearing idlers, hanging type idlers, triple chain idlers, reversible idlers, variable slot angle idlers, transition Idlers, V-shaped idlers, etc.

(2) Parallel idlers include ordinary idlers, comb-like idlers, forward inclined idlers, steel rubber idlers, spiral idlers, etc.

(3) Self-aligning idlers include universal, friction reversible idlers, powerful idlers, beltred idlers, spiral idlers, combined idlers, etc.

(4) Impact idlers include spring plate idlers, impact ring idlers, strong impact idlers, adjustable elastic idlers, hanging idlers, etc.

Ceramic conveyor idlers are simply referred to as ceramic idlers. This product not only has the characteristics of wear resistance, acid and alkali resistance, oxidation resistance, stable operation, anti-theft, etc., but ceramic conveyor idlers can effectively prevent the belt from running away, reduce local loss of the belt, and extend the belt Service life reduces the frequent replacement of idlers for use in harsh outdoor environments. Ceramic idlers have a much longer life than ordinary idlers. Ceramic conveyor idlers have high strength and good abrasion resistance. Ceramic idlers have a long service life and can reduce belt abrasion. High temperature resistance, oxidation resistance, strong corrosion resistance, ceramic conveyor idlers are suitable for various harsh environments. No static electricity, sparks are not easy to occur during abrasion and collision, and ceramic idlers are suitable for easy environments such as coal mines. Stable performance, can effectively prevent the belt conveyor from drifting, pulling forks and generating heat.

Nylon conveyor idler has a low coefficient of friction, abrasion resistance, and is unlikely to damage the belt. It has excellent self-lubricity, and can be used under harsh environmental conditions without oiling during use. It is not easy to jam and has good anti-magnetic properties. Corrosion resistance, strong aging resistance, resistance to weak acids, weak alkalis and organic solvents, non-toxic and non-polluting, can withstand repeated shocks and vibrations. The nylon idler itself is light weight, only one third of the metal parts, easy to install, low maintenance rate, low noise, stable operation, energy saving, can improve the service life of the nylon idler, dustproof, good waterproof performance, in the environment of multiple ash It is not easy to get water in use.

Nylon conveyor idler features:

1. Nylon conveyor idler has extremely high abrasion resistance, extremely low friction coefficient, and it is not easy to wear the belt;

2. Nylon idler has excellent self-lubrication, no oil is needed, and it is not easy to be stuck under severe conditions;

3. The nylon conveyor idler has antistatic, anti-smoldering, aging resistance, and chemical (acid, alkali and organic solvent) corrosion resistance;

4, can withstand repeated shocks and vibrations;

5. The working temperature range of nylon idler is: -40 ℃ ~ 80 ℃;

6, excellent mechanical properties, light weight, easy installation, no maintenance required;

7. Nylon conveyor idler with low noise (3-7DB) runs smoothly and has a long life (3-5 times the life of metal idler)

Performance characteristics of troughing conveyor idlers:

1. The troughing idler has the characteristics of corrosion resistance: acid and alkali salts are hard to corrode it.

2. Trough conveyor idler has high hardness: strong abrasion resistance.

3. Good sealing performance: The troughing idler is fully sealed, and plastic labyrinth seals are installed at both ends. The oily grease will not leak and the rolling shaft can be kept for a long time. The troughing idler runs under the fully sealed state.

4. Slotted idler ceramic surface: an oxide film is formed, the surface is smooth, no material is adhered, and the friction coefficient with the conveyor belt is small, which reduces the driving force of the hoisting.

5. Trough idlers have a long service life: Trough conveyor idlers use 2 to 5 times longer than steel idlers, and can reduce belt wear. The belt does not run away, extending the belt service life.

6, low operating costs: trough-shaped idlers can reduce the overall cost of the belt conveyor and reduce maintenance hours.

Trough conveyor idlers are widely used in all places with large open-air dust and high corrosive environments, such as mines, power plants, steel plants, stone plants, cement plants, coal washing plants, salt plants, alkali plants, chemical fertilizer plants, wharfs, etc. Trough conveyor idlers are often used.

Impact conveyor idler, used to reduce the impact of blanking on the conveyor belt at the receiving place of the belt conveyor. It is a type of conveyor idler developed for corrosive environments such as coal washing plants, coking plants and chemical plants. It itself It has ten times more toughness than ordinary metal, five times longer life than traditional column shoes, corrosion resistance, flame retardant, antistatic, light weight, etc. It is widely used in mining. The polymer material special for the idler body has mechanical properties similar to bronze, has good abrasion resistance, and has good self-lubricating properties without hurting the belt. The impact idler has excellent corrosion resistance. The idler body and seal are made of high-molecular materials, which are resistant to corrosion. Used in corrosive occasions, the service life can reach more than 5 times that of ordinary idlers.

The impact conveyor idler is light in weight and has a small rotational inertia. The special polymer material for the idler is light in weight and its specific gravity is one-seventh that of steel. The idler made of this material weighs about one-half the weight of an ordinary idler and has a small rotational inertia. The friction is small.

Impact idlers are installed below the receiving section of the conveyor to reduce the impact of the material on the conveyor belt when the material is dropped, so as to lengthen the service life of the conveyor belt. The distance between the impact idlers is generally 100-600 mm.

In terms of installation, the impacting conveyor idlers are firstly to improve the installation density; the second is to check frequently and replace the damaged idlers in time. It is recommended to install a impact air lock for a conveyor belt with a large blank drop and replace the impact idler with a impact bed. In terms of purchasing, according to the characteristics of the impact idler, the following points should be noted: the radial runout of the idler, the flexibility of the idler, the amount of axial movement, the dustproof performance of the conveyor idler, the waterproof performance, the axial load bearing performance of the idler, Impact resistance of idlers, etc.

(1) Temperature protection of impact conveyor idler

When the temperature of the belt conveyor idler and belt friction exceeds the limit, the detection device installed next to the idler sends an over-temperature signal. After the signal is received by the receiver, the execution part will be activated after 3s delay, and the power supply to the motor will be cut off. Stops to protect the temperature.

(2) Conveyor Idler speed protection

If the conveyor fails, such as the motor burned out, the mechanical transmission part is damaged, the belt or chain is broken, the belt slips, etc., the magnetic switch in the accident sensor SG installed on the conveyor is not closed or cannot be closed at normal speed. At this time, the control system will delay the time according to the inverse time characteristic, and the speed protection circuit will work to make the execution part act and cut off the power supply to the motor to avoid the accident from expanding.

(3) Coal level protection of impact idler coal bunker

There are two coal level electrodes in the coal bunker. When the coal bunker can not put coal because there is no empty car, the coal level will gradually rise. When the coal level rises to the high electrode, the coal level protection action starts from the first belt conveyor. Each conveyor stopped in turn because of coal piled at the tail.

Influencing factors:

1. Radial runout of the conveyor idler (this index directly affects the stability of material transportation)

2. Axial series momentum (directly affects the service life of the conveyor idler)

3. Flexibility (affects the service life of the idlers and the service life of the belt, and the driving power of the whole machine)

4. Waterproof performance (affects the service life of the conveyor idler)

5. Dust-proof performance (affects the service life of the conveyor idler)

6. Axial load capacity (affects the service life of the conveyor idler)

7. Impact resistance (affects the service life of the conveyor idler)

8. Rotation resistance (affects the service life of the belt).

working principle:

The conveyor idlers drive the idler tube body, bearing housing, bearing outer ring, and seal ring to perform rotary motion through the friction between the belt and the idler, and realize the logistics transmission with the belt.

Use operation:

1. Before using the conveyor idlers, carefully check the appearance for serious bump damage. The rotating idlers should rotate flexibly without jamming.

2. The installation distance of the supporting idlers should be determined by scientific calculations according to the type of logistics and the characteristics of the conveyor. Avoid over-sparse or dense installation.

3. The conveyor idler installation should be adapted to avoid friction between each other.

Maintenance:

1. The normal service life of the conveyor idler is more than 20000h, and generally no maintenance is required. However, according to the place of use and the size of the load, a corresponding maintenance date should be established, timely cleaning and oil injection maintenance, and timely cleaning of floating coal. Replace the idlers with abnormal noise and non-rotation in time.

2. When replacing the bearing, the bearing holder opening must be outward. After the bearing is installed in the idler, the proper clearance should be maintained and it should not be crushed to death.

3. The seals should use original accessories. They should be packed into the conveyor idlers separately during assembly, and should not be put together for assembly.

4. The conveyor idlers in use should be prevented from hitting the idler tube body with heavy objects.

5. In order to ensure the sealing performance and use performance of the conveyor idler, it is prohibited to disassemble the idler at will.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China