The background for developing long-life conveyor idlers is that traditional idlers have problems with a short lifespan and being easily damaged. This not only increases maintenance costs but also affects production efficiency. In order to address these issues, our team of engineers began researching and designing more durable conveyor idlers that can not only significantly reduce maintenance costs but also improve production efficiency and safety.

The new conveyor idlers have a wide range of applications and good environmental compliance. They do not require refilling during their lifecycle and are maintenance-free. The conveyor idlers use a contact waterproof seal and have an operating life of more than 36,000 hours, making them highly reliable and long-lasting. With these new and improved conveyor idlers, industries can reduce their maintenance costs and improve their production efficiency.

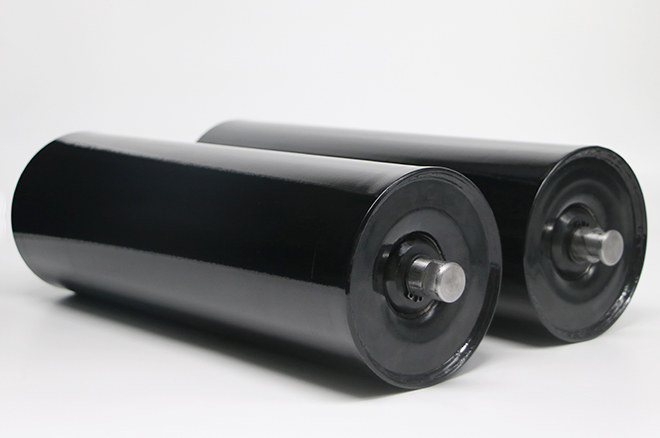

We have considered various factors when designing this series of conveyor idler to minimize starting torque, high efficiency, long life, minimum maintenance, and maximum load capacity. The conveyor idler have ideal static and dynamic equilibrium to ensure high-speed applications. The steel tube accept the high-frequency welded pipe for the national standard conveyor idler. The special machine for cutting work is used during conveyor idler processing. The bearing house of the conveyor idler is formed by cold plate stamping, and the accuracy grade is ISOM7, which can make the starting torque smaller.

The housing and bearing block of the roller are welded with a CO2 gas maintenance automatic welding machine, which makes the overall structure high in strength, can ensure good accuracy, and minimizes radial unbalanced elements. The shaft is cold drawn to ISOH6 to ensure the accuracy of the bearing. Bearings and sealed bearings use single-row radial ball bearings such as SKF, FAG.

Under a specific temperature environment, even a small amount of water and gas entering the conveyor idler will rust it, thereby reducing the service life of the conveyor idler. To avoid this phenomenon, JIENASI adopts a series of sealing measures. Starting from the outside, a corrosion-resistant zinc-aluminum alloy cover fixed on the shaft prevents particles larger than one millimeter from entering the roller.

JIENASI conveyor idler are installed with low-friction rubber lip seals to prevent smooth grease from flowing out of the conveyor idler and external liquids from entering the conveyor idler. The conveyor idler weight does not increase after running in water for 24 hours; The ternary labyrinth seal made of carbonate material; these maintenance measures effectively prevent external atmospheric media from entering the bearing chamber.

All in all, this technological innovation has brought great changes to the modern logistics and production industry, making idlers more reliable and efficient in practical applications. In the future, we can expect the continuous improvement and promotion of this technology to make more contributions to the development of the logistics industry and the improvement of production efficiency.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China