The conveyor idler is an important accessory of the belt conveyor. Its weight accounts for about 1/3 of the overall weight of the conveyor, according to the survey, the service life of conveyor idlers is generally 8000-10000h. In the process of conveying materials, every minute of use is accompanied by consumption of conveyor idlers, and the percentage of damage is extremely high. Therefore, it is very important to improve the manufacturing quality of conveyor idlers to reduce the energy consumption and conveying efficiency of belt conveyors. The main reasons for conveyor idler damage and countermeasures:

(1) Bearing quality.

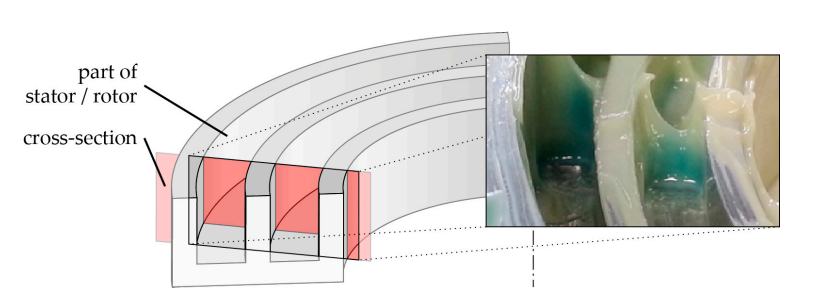

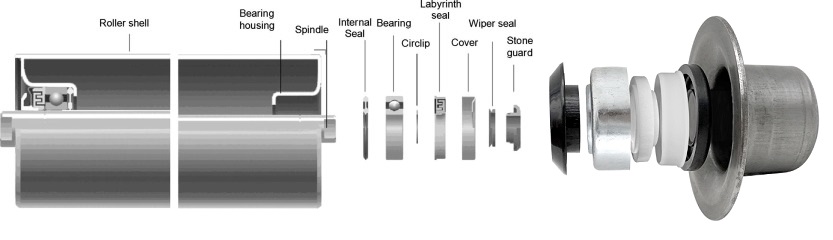

The service life of the conveyor idler mainly depends on the performance of the bearings and seals. If the bearings and seals used by the conveyor idler have good performance, the service life of the conveyor idler will be greatly extended. The test results show that the friction resistance of the bearing accounts for about 1/4 to 1/8 of the rotation resistance of the conveyor idler. At present, the bearing models used by conveyor idlers are 6204KA, 6205KA, 6305KA, 6306KA and other rolling bearings.

Bearing quality determines the operating life of the conveyor idler. At present, a considerable number of manufacturers choose low-priced, low-quality bearings to assemble idlers, and the dimensional accuracy, hardness and clearance of their inner and outer diameters cannot meet the requirements of technical standards. Therefore, brand bearing manufacturers must be used to ensure quality.

(2) The quality of the bearing house.

Poor machining accuracy of the inner hole of the bearing house leads to the circumferential movement of the bearing in the bearing house, which is one of the reasons for damage to the conveyor idler.

The stamping bearing house needs to go through 3 sets of stamping dies to complete the finished product. The quality of the stamping die determines the quality of the bearing house, which also determines the life of the bearing, and is ultimately related to the service life of the conveyor idler. Therefore, conveyor idler manufacturers should follow up the assessment and conduct management review to ensure that they are qualified in the procurement control list, and inspect the purchased bearing housings in strict accordance with the inspection procedures.

A Step-by-Step Guide to Selecting the Right Conveyor Idlers 2023

10 basic factors to consider when choosing a suitable conveyor idler

Only one table can help you easily choose the right conveyor idler set (belt width from500~2400mm)

3 key parts that most affect the operating life of conveyor idlers

(3) Welding of the bearing house and the conveyor idler tube body.

The welding quality of the bearing house and the pipe body is poor, causing axial disengagement or dust and water immersion in the conveyor idler bearing, resulting in damage to the conveyor idler. Therefore, argon or CO2 gas shielded welding should be selected for welding, and parameters such as welding voltage, welding current, gas flow rate, wire feeding speed, and pipe body selection line speed must be strictly followed. The welding equipment and welding wire materials should be inspected in advance.

(4) Selection of grease.

Improper selection of grease will cause damage to the bearing, which in turn will cause damage to the conveyor idler. The MT821-2006 coal industry standard clearly requires the selection of 3# lithium-based grease, otherwise, the conveyor idler will be damaged after running for several hours.

What is emphasized here is: For conveyor idler bearings operating at -25°C, a special type of low-temperature-resistant aviation grease must be selected.

(5) conveyor idler assembly.

Conveyor idler assembly not only needs to make special process equipment, but also must be completed on the conveyor idler press machine. Only in this way can the axial specified assembly pressure of the bearing, seal assembly and retaining ring be controlled. It is also required that the constructor must pass the technical training and pass the assembly fitter to operate. In short, the conveyor idler assembly should be controlled as a key process point, and the key process operation instructions should be compiled.

The conveyor idler is the main consumable and vulnerable part of the belt conveyor. It has a large quantity and a wide range, and its quality directly affects the normal operation of the conveyor. Therefore, improving the quality of conveyor idlers has a great correlation effect on reducing energy consumption, saving costs, and increasing operational reliability. With the development of conveyors in the direction of long-distance, large-capacity, and high-speed, higher requirements are put forward for conveyor idlers in terms of sealing structure, processing quality, bearings, bearing housings, sealing components, and grease. Strict control of process, component quality, and scientific management of the whole process of grease selection can fundamentally improve the quality of conveyor idlers, thereby prolonging the maintenance cycle of the conveyor and ensuring that the belt conveyor can play its due role in high-yield and efficient mines.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China