When we choose the type of conveyor idler, it is easy to ignore the type of steel pipe. Most of the opinions think that seamless steel pipe is better because of its high strength and high bearing pressure, some people think that welded pipe is better because it is economical, is it true? So which kind of steel pipe is more suitable for the conveyor idler? Please see the end, the conclusion may surprise you.

First of all, let's talk about the difference between seamless steel pipe and welded pipe:

1. Different processing methods: seamless steel pipes are made of round steel through heating, perforating, hot rolling or cold drawing, and welded pipes are formed by bending steel plates or steel strips through high-frequency welding.

2. Different pressure-bearing properties: seamless steel pipes usually have sufficient wall thickness and can withstand higher pressures, and are often used in high-pressure equipment and machinery industries; welded pipes are not as good in pressure-bearing properties as seamless steel pipes, so they are mostly used in conveying equipment or non-pressure pipeline industries for transporting gases and liquids.

3. Different shapes: seamed steel pipes have straight seam welding and spiral welding, so there are obvious weld bars on the surface, while seamless steel pipes do not.

4. The cost is different: the production process of seamless steel pipe is relatively complicated. If there is a requirement for wall thickness, it needs to be processed by cold drawing and other processes. Therefore, the cost of seamless steel pipe is greatly increased, while the price of welded pipe is relatively cheaper.

So which steel pipe is more suitable for conveyor idlers? We know that in the operation of the conveyor idler, it is not the pressure bearing capacity of the steel pipe that directly affects the life of the conveyor idler, but the concentricity, because the material transportation is continuous during the operation of the conveyor idler, as long as the thickness of the steel pipe meets the basic requirements, the conveyor idler can easily carry a huge material weight, but if the concentricity of the conveyor idler is not good, it will directly threaten the service life of the conveyor idler.

Which concentricity is better between seamless steel pipe and welded pipe?

Let's take a look at the manufacturing process of the two steel pipes:

The seamless pipe manufacturing process is at a temperature of 2200 ° F in a stainless steel billet punching out a hole in this high temperature tool steel by stamping and drawing becomes soft and spirally from the hole shaped out, such uneven wall thickness of the pipe and the eccentric high. Thus, ASTM standard allow the wall thickness difference of seamless pipes is bigger than the welded pipes.

The welded tube is made by precision cold-rolled plates (4-5 feet) per roll width, so the welded pipe wall thickness tolerances are small, and the entire circumference of the wall thickness is very uniform. The seamless pipe is more suitable for transporting liquid or gas with huge internal pressure.

In short, the low concentricity and the uneven thickness of the pipe wall are the fatal problems of the conveyor idler. The low concentricity will lead to the unbalanced assembly of the two ends of the conveyor idler during the production process, and the two bearings are not on the same axis, leading to the radial jumps(run-out) during the conveyor idler running, which directly reduces the life of the conveyor idlers.

The uneven wall thickness of the pipe will lead to uneven centrifugal force and unbalanced forces during the conveyor idler running. When the conveyor belt speed is faster than 1.5 m/s, the radial jumping and uneven wall thickness will directly cause the entire conveyor line to be in a resonance state, accelerate the fatigue of the driving equipments (motors and pulleys) and accessories, and shorten the service life of the conveyor line.

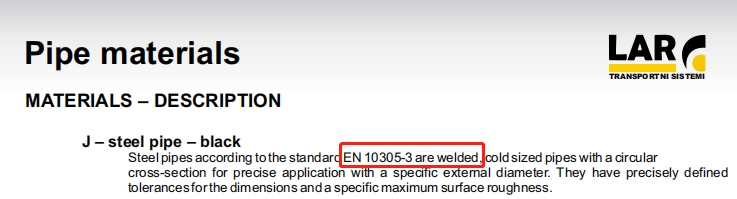

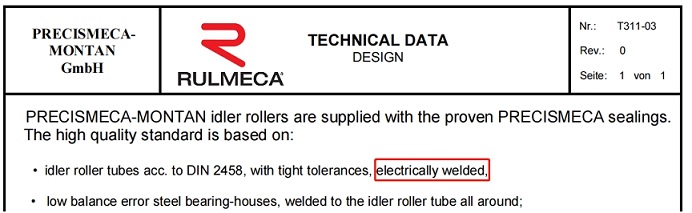

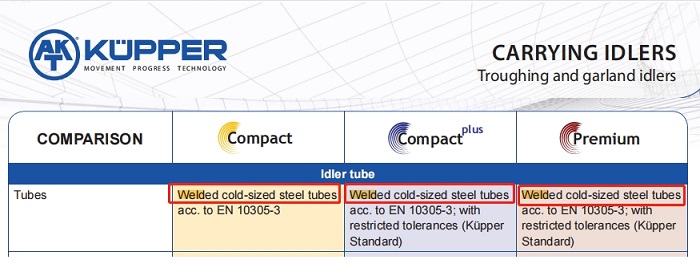

This is the reason why all the conveyor idler manufacturers in the world use welded pipes, please see the following technical parameters of three famous manufacturers in the world, they all use welded pipes:

A Step-by-Step Guide to Selecting the Right Conveyor Idlers 2023

10 basic factors to consider when choosing a suitable conveyor idler

Only one table can help you easily choose the right conveyor idler set (belt width from500~2400mm)

3 key parts that most affect the operating life of conveyor idlers

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China