What is the difference between "conveyor idler" and "conveyor roller"?

Commonality: "Conveyor Idler" and "Conveyor Roller" are essential components in conveyor systems. Their primary function is to support and guide the conveyor belt or material, reducing friction to ensure smooth transportation. They are typically made from similar materials, such as steel, stainless,HDPE, or polyethylene, and consist of rollers, bearings, and shafts. Both are suited for use in various industrial environments.

Difference: "Conveyor Idler" typically refer to a trough-shaped unit composed of multiple rollers and a bracket, primarily used in long-distance bulk material transport systems, they help maintain rubber conveyor belt tension, stability, and alignment and are commonly used in industries like coal mining, ore, and cement handling. In contrast, "Conveyor Roller" are individual rollers forming a horizontal conveyor line, more commonly used for short-distance transport or the handling of single items, such as in logistics, manufacturing, food handling, and packaging, they can be either powered (driven) or non-powered.

"Conveyor Idler" and "Conveyor Roller" are both key components in conveyor systems, generally speaking, conveyor idlers specifically refer to trough-shaped units used in heavy-duty bulk material transport industries, while conveyor rollers can be applied to both long-distance bulk material transport and short-distance logistics transport. Although their names are often used interchangeably, this does not affect people's understanding of their respective uses and applications.

Belt Conveyor roller / Carrying roller

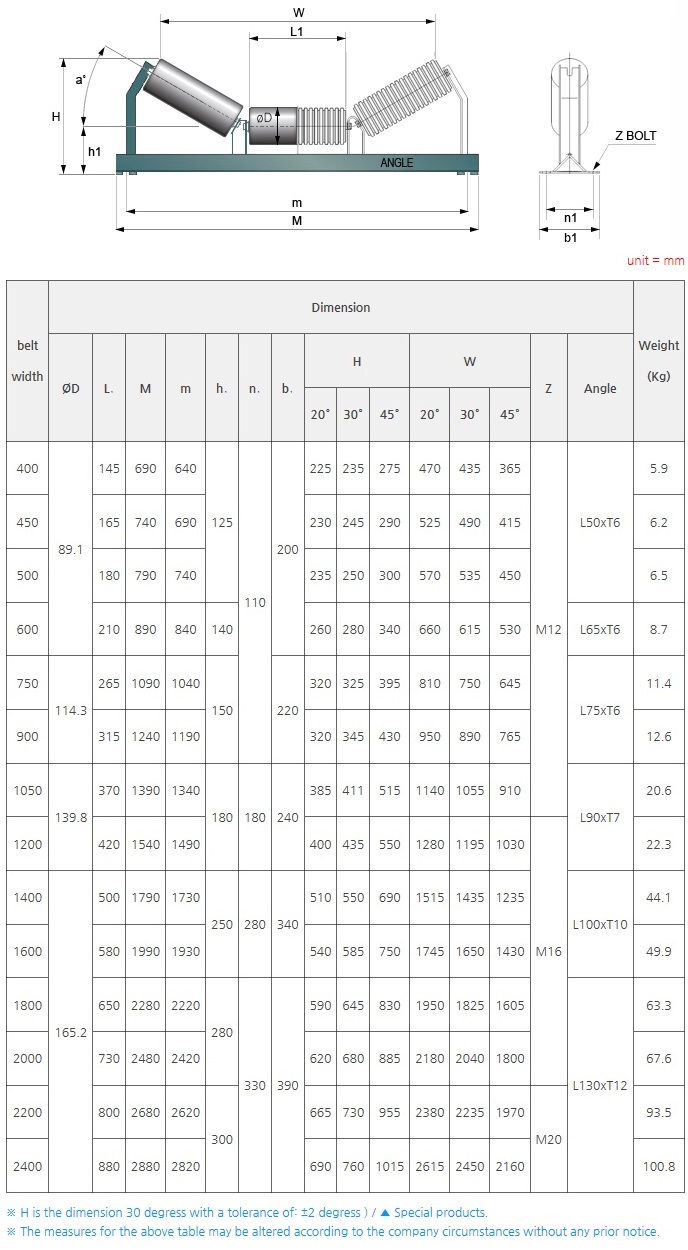

Conveyor rollers(station/bracket)are an essential component of heavy-duty material handling systems in industries such as coal and mining, power, and cement. The conveyor roller are designed to support and guide the conveyor belt along its path, ensuring smooth and efficient operation.

Detailed conveyor roller feature:

Conveyor roller: Available in diameters ranging from 50 mm to 219 mm (2 1/2" to 8 5/8"), with lengths from 190 mm to 3400 mm, to suit a wide range of conveyor systems.

Roller Tube: Made from Q235 (equivalent to SS400/JIS G3101/EN10025/ASTM A36 ) steel for durability and strength.

Roller Shaft: Constructed from 45# (equivalent to DIN:C45/EN:C45/JIS:S45C/ASTM A1045 )steel for reliable performance.

Bearing: Equipped with single and double row deep groove ball bearings, with 2RZ and 2Z options available, and C3 clearance for enhanced efficiency and reduced friction.

Seals system: Features a grease retaining inner seal with multi-stage labyrinth design, along with a retention cap, to prevent dust and debris from entering the bearing.

Lubrication: Uses lithium soap type grease with rust inhibitors, to ensure smooth and reliable operation.

Welding technology: Utilizes mixed gas shielded arc welding for strong and consistent welds.

Painting technology: Offers a variety of painting options, including ordinary painting, hot galvanized painting, electric static spraying painting, and baked painting, to suit the specific needs of each application.

Overall, our conveyor irollers are designed and built to meet the rigorous demands of heavy-duty material handling systems, ensuring smooth and efficient operation and long-lasting performance.

JIENASI Automatic Conveyor Roller Production Line--2024

The new ultra-long-life conveyor rollers developed by JIENASI utilize advanced T4003CR stainless steel in conjunction with SKF bearings, achieving a standard lifespan of up to 60,000 hours, with the potential to reach a maximum of 100,000 hours. What makes this stainless steel so wear-resistant, and in which industries can conveyor rollers using T4003CR be applied?

T4003CR, equivalent to the European standard 1.4003, is a practical ferritic stainless steel often used as a substitute for low carbon steel. T4003CR possesses a range of advantages typical of ferritic stainless steels, including high strength, excellent corrosion resistance, and outstanding wear resistance. It is weldable, formable, durable, and enables lower maintenance requirements. Its characteristics are as follows:

T4003CR Chemical Composition

|

Element |

Content |

|

Carbon |

0.15-0.20% |

|

Silicon |

0.75-1.25% |

|

Manganese |

1.25-1.75% |

|

Phosphorus |

≤0.03% |

|

Sulfur |

≤0.03% |

|

Chromium |

16.00-18.00% |

|

Nickel |

3.00-4.00% |

T4003CR Mechanical Properties

|

Property |

Value |

|

Tensile Strength |

≥520 MPa |

|

Yield Strength |

≥205 MPa |

|

Elongation |

≥35% |

Corrosion Resistance

T4003CR stainless steel exhibits excellent corrosion resistance and can be used in various corrosive environments. Its corrosion resistance is particularly outstanding in environments containing chloride ions and sulfate ions. In reducing acids and oxidative acids environments, it also performs well. conveyor idlers using T4003CR can be applied in industries such as fertilizer, petrochemical, food, pharmaceutical, papermaking, sewage treatment, and metal processing.

Processing Performance

T4003CR stainless steel possesses good processing characteristics, adapting to various processing requirements. It has good plasticity and weldability, allowing for deep drawing, bending, and edge rolling operations. Additionally, it demonstrates good fatigue resistance and stress corrosion resistance, making it suitable for use in environments subjected to repetitive loads. Therefore, conveyor idlers using T4003CR exhibit excellent wear and corrosion resistance.

In summary, T4003CR stainless steel is a high-strength, corrosion-resistant, and easily processable material, with its excellent performance finding widespread applications in various fields. However, it is essential to consider the specific usage environment when selecting materials, as each material has its limitations.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China