An important part of the heavy-duty conveyor idler belt conveyor, the role of the conveyor idler is to support the rubber conveyor belt and the weight of the material and to make a rotary motion with the movement of the conveyor belt. Widely used in mining, coal, sand, logistics, and other bulk material transportation fields. Due to the wide application of conveyor idlers, idlers of different types and functions have been produced. The following will introduce some common types of conveyor idlers and their uses and advantages and disadvantages, we hope to help you choose a suitable conveyor idler.

According to the tube material of the conveyor idler, it can be divided into metal conveyor idlers, polymer conveyor idlers, ceramic conveyor idlers, rubber conveyor idlers, and metal conveyor idlers.

1. Metal conveyor idler: This kind of conveyor idler is the most widely used material, the main material is SS400/A36/JIS3101/Q235, etc., because this steel material has good impact resistance, stable performance, and is not easy to deform and the price is low, so it occupies nearly 85% of the current conveyor idler market share. The disadvantage is that the wear resistance and acid and alkali resistance are not good, and it is easy to rust in a humid environment.

2. Polymer conveyor idler: This kind of conveyor idler material is also called HDPE or UHMW-PE. It has excellent wear resistance, acid and alkali resistance, low surface hardness, small friction coefficient, friendly to the conveyor belt, low noise and long service life. long. The disadvantage is that it is expensive and the overall structure is unstable in extreme environments.

3. Ceramic conveyor idler: It has the characteristics of insulation, wear resistance, corrosion resistance, and not easy to stick. The disadvantage is that it is very heavy and has poor impact resistance.

4. Rubber coating conveyor idler: light weight, good shock absorption effect and friendly to the conveyor belt, but the friction is large, not corrosion-resistant, and the rubber is easy to age.

5. Nylon conveyor idler: The body material of the conveyor idler is made of nylon material. Like polymer materials, it also has excellent acid and alkali resistance and corrosion resistance, but its wear resistance is worse than that of HDPE, and its hygroscopicity is better than that of HDPE.

Second, according to the use of the conveyor idler, it can be divided into carrying conveyor idler, parallel idler, impact idler, self-clean conveyor idler.

1. Carrying conveyor idler: It is the most widely used type of conveyor idler. It mainly forms a troughing conveyor idler group with the troughing bracket. It is installed on the upper part of the conveyor line and used to carry and transport bulk materials. It can be divided according to the angle of the troughing. 15°, 25°35°45° and so on, among which 35° is the most commonly used groove angle.

Carrying conveyor idlers are further divided into self-aligning conveyor idlers and taper cone conveyor idlers. This kind of conveyor idlers can automatically adjust the track of the conveyor belt in the conveyor belt through a special bracket with self-aligning function, thereby preventing the conveyor belt from misalignment phenomenon.

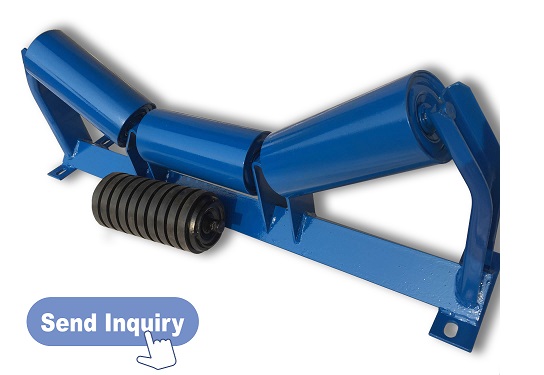

2. Return conveyor idler: The return conveyor idler is mainly used to support the return part of the conveyor belt. Its main structure is the same as that of the troughing conveyor idler, but the length is longer than the troughing idler, which is about 10% longer than the conveyor belt width.

3. Impact conveyor idler: The surface of the Impact conveyor idler is wrapped by some impact rubber ring, and it is installed under the feeding section of the conveyor, which can effectively reduce the impact on the conveyor belt and prolong the service life of the conveyor belt.

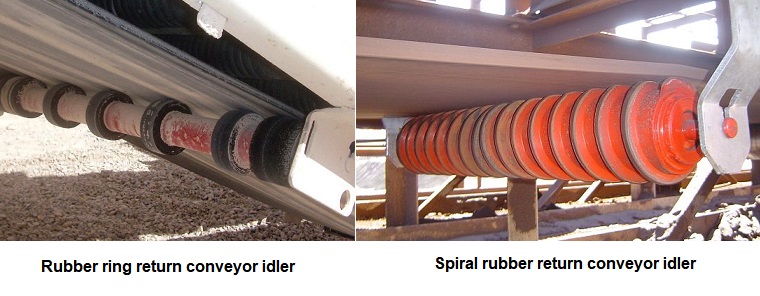

4. Self clean conveyor idlers: mainly used to clean up the sticky material on the conveyor belt and keep the surface of the conveyor belt clean, this type of conveyor idler is more common on the return idler

5. Suspension idler: This kindly of conveyor idler also called "garland conveyor idler", this conveyor idler supports the operation of the conveyor belt by hanging on the frame of the conveyor, it is usually used on a long-distance conveyor line. The advantage is that there is no bracket support, so the cost is reduced, and the space is saved, but it is determined to be unstable and have low carrying capacity.

Conveyor Idler Workshop----Baoding Zhuoli Machinery Co.,Ltd.

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China