The impact conveyor idler is mainly used at the material receiving place of the belt conveyor to slow down the impact of the falling material on the conveyor belt. Generally, where the material drop is greater than 2.5 meters, we use the impact conveyor idler, because the impact conveyor idler is composed of several highly elastic impacts. Composed of rubber rings, it can greatly absorb the huge kinetic energy generated by materials falling from a high altitude, this can not only reduce the impact and wear of the conveyor belt by materials, but also prevent the conveyor belt from being torn by hard objects. If it is combined with a impact bed, the effect will be better.

The impact conveyor idler will definitely be damaged if it is used for a long time, but sometimes it will be damaged if it is not used for a long time. What is the reason? Let's find out together!

There are two reasons for the short-term damage of the impact conveyor idler:

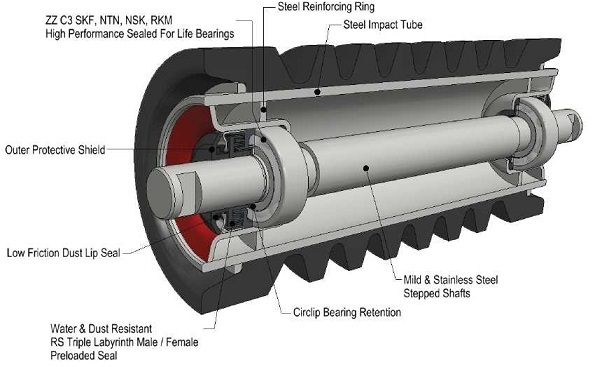

1. Due to the large dust at the blanking point, the sealing function of the impact conveyor idler is poor, and fine dust particles enter the bearing, causing rapid wear of the bearing and eventually causing damage to the impact conveyor idler;

2. The impact rubber ring is basically made of recycled rubber. Not only is it poor in elasticity, it is not wear-resistant and impact-resistant, and its service life is only about one year. It cannot effectively absorb the impact and cause serious damage to the conveyor belt.

3. The weight of the material is too large, resulting in excessive impact on the impact conveyor idler when the material falls, exceeding the design load capacity of the impact conveyor idler, resulting in serious deformation of the structure of the conveyor idler.

4. The material drop is too large. If the weight of the material is not large, but the drop is too large, the impact conveyor idler will still be damaged, because the long-term acceleration of gravity will make the impact conveyor idler suffer from strong and frequent impacts, which will cause damage to the conveyor idler

5. The design of the conveyor idler is unreasonable, such as the use of too thin steel pipes and too thin shafts. Such a structure makes it difficult for the impact conveyor idler to withstand strong impact.

Solution:

1. The labyrinth sealing system is adopted. This sealing system is mature and stable, and the sealing effect is good. The bearing adopts sealed bearings, which can ensure the sealing effect of dust to the maximum extent, thereby prolonging the service life of the impact conveyor idler. ;

2. The impact rubber ring is replaced with the rubber ring made of automobile tire rubber. This rubber ring has excellent wear resistance, impact resistance, tear resistance, aging resistance, high elasticity and other performance properties, which improves the service life of the impact conveyor idler About 10 times, even better than the effect of the impact bed

.3. For the production environment where the material is too heavy or the drop is too large, it is best to use it in conjunction with the impact bed, which can minimize the damage to the impact conveyor idler caused by the impact force, thereby improving the transportation efficiency.

4. Use thicker steel pipes and larger diameter shafts. We recommend that the thickness of steel pipes for impact conveyor idlers should not be less than 4.5mm, and the diameter of the shafts should not be less than 25mm, so that they can withstand greater impact

Contact: Export Department

Phone: +86 15097752737

Tel: +86 0312 5308005

Company: Baoding Zhuoli Machinery Co.,Ltd

Add: 3934 Tower3,Weilaishi building,Xiongan New Area.Baoding city,China